Tip of the Day 183: Thick and Thin Wall: The Molder’s Misery

Many of our readers have read or been taught how important it is to design parts with constant wall thickness. I asked some of our consulting team, “When did you last see such a part?” Apparently they are becoming rare. We are now fining many more parts with varying wall thickness.

The molding quadrant and the discussion of thin and thick wall now leads us to this “mixed” wall thickness problem. We’ll start here with thick-to-thin. The next tip covers thin-to-thick.

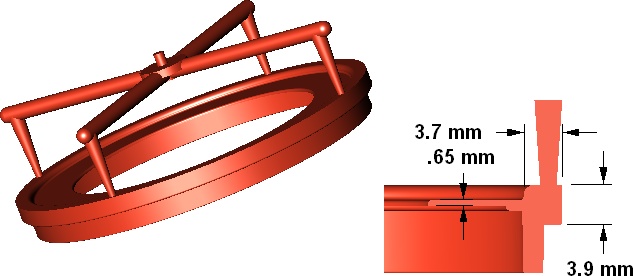

Example: A ring with a flange

You may easily imagine what will happen to the material flowing into the flange vs. the ring body. Let’s walk through it.

- The pressure loss in flowing plastic is always the same from the gate to the flow front. The flow front is ~0 pressure and the gate is just one point (effectively).

- That pressure loss is relative to flow rate, length AND to the inverse of wall thickness CUBED! 1/T3 or 1/(T x T x T).†

- In order to have the same pressure loss in the thin flange as in the thick ring section, something must balance to get equal pressure loss. Thus the material in the flange flows a much shorter distance in the same time the material in the ring flows significantly further. This means a slow progression of flow front in the flange.

- The flow in the flange is SO slow that the heat supply keeping the “pipe” (flow channel) open is not enough to prevent freezing. As mentioned in thin wall parts, we hit the “time barrier” in a thin section where freezing occurs.

- Of course, as cooling occurs the material becomes even harder to flow and soon shuts off flow entirely in the flange opposite the gate. With the material stalled, the flow front wraps back around itself from the knit line creating air traps inside the flow front (note the one on the right side). This creates the odd scenario where the last place to fill is a point right near the gate.

What to do?

- Don’t BUILD parts like that!

Of course we rarely have a choice. So…

- Raise the melt temperature?

Perhaps. But the added heat load will make it harder to cool the thick ring.

- Fill faster? (3.5 x faster shown here).

This does result in some improvement in the back-flow. But we can see that the last place to fill is still opposite the gate. The flow front keeps moving, at least. But the flow front opposite the gate only progresses as pressure builds up around the ring.

- Prevent the flange from cooling as quickly?

A tricky bit of tooling, probably. Still, remember that the 4th plastic variable we are trying to match is Plastic Cooling: rate and time. It would be nice if the flange froze at roughly the same time as the thick ring. To do that with different wall thicknesses would require a hotter mold temperature under the flange than the ring.

- Other ideas?

† For those following this algebraically pressure loss is proportional to…

Thus a 3.5 times reduction in thickness must be balanced by a 43 times (3.53) reduction in flow rate, flow length or a combination of the two. This is to get the same pressure loss to all points on the flow front.

This does not count viscosity vs. shear, flow front width and frozen layer thickness, of course. But it helps conceptually. The actual power of thickness seems to emperically fall around 2.