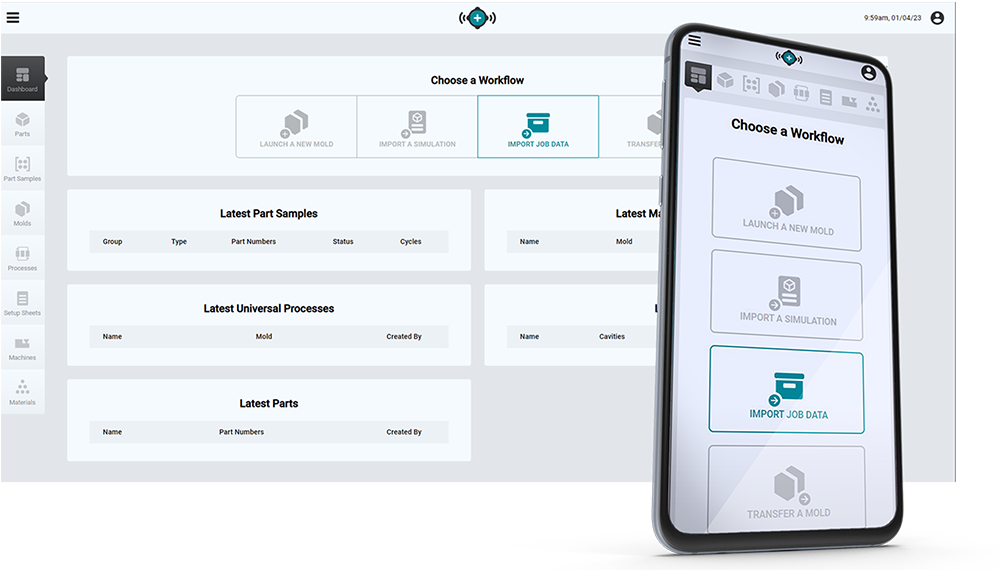

Leverage the power of knowledge at your finger tips

Raise your bottom line, improve operational efficiency, and stay competitive

Make smart business decisions quickly

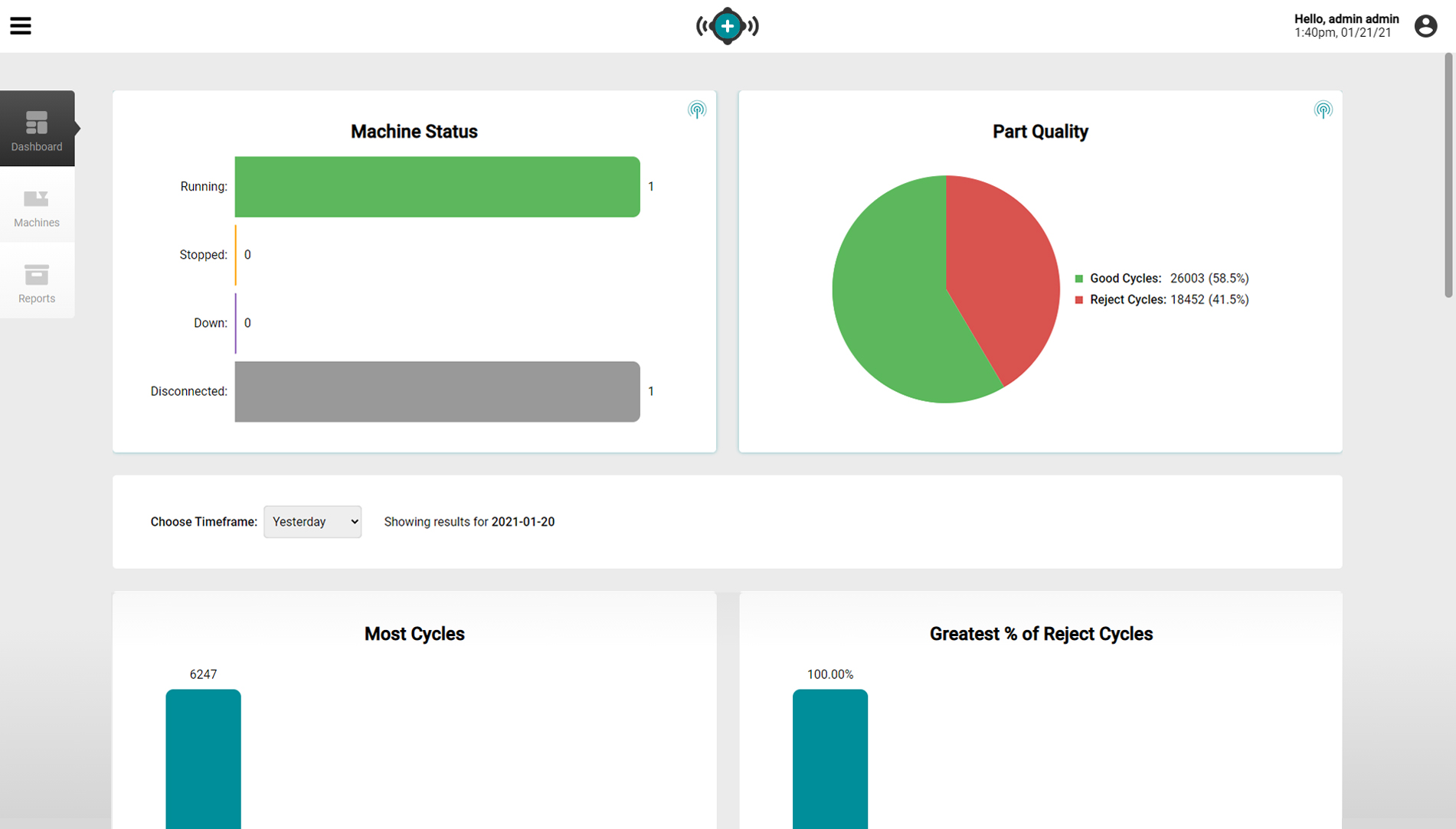

- Understand where facilities excel or could be improved

- Quickly troubleshoot issues on the go

- Easily learn what your data is telling you

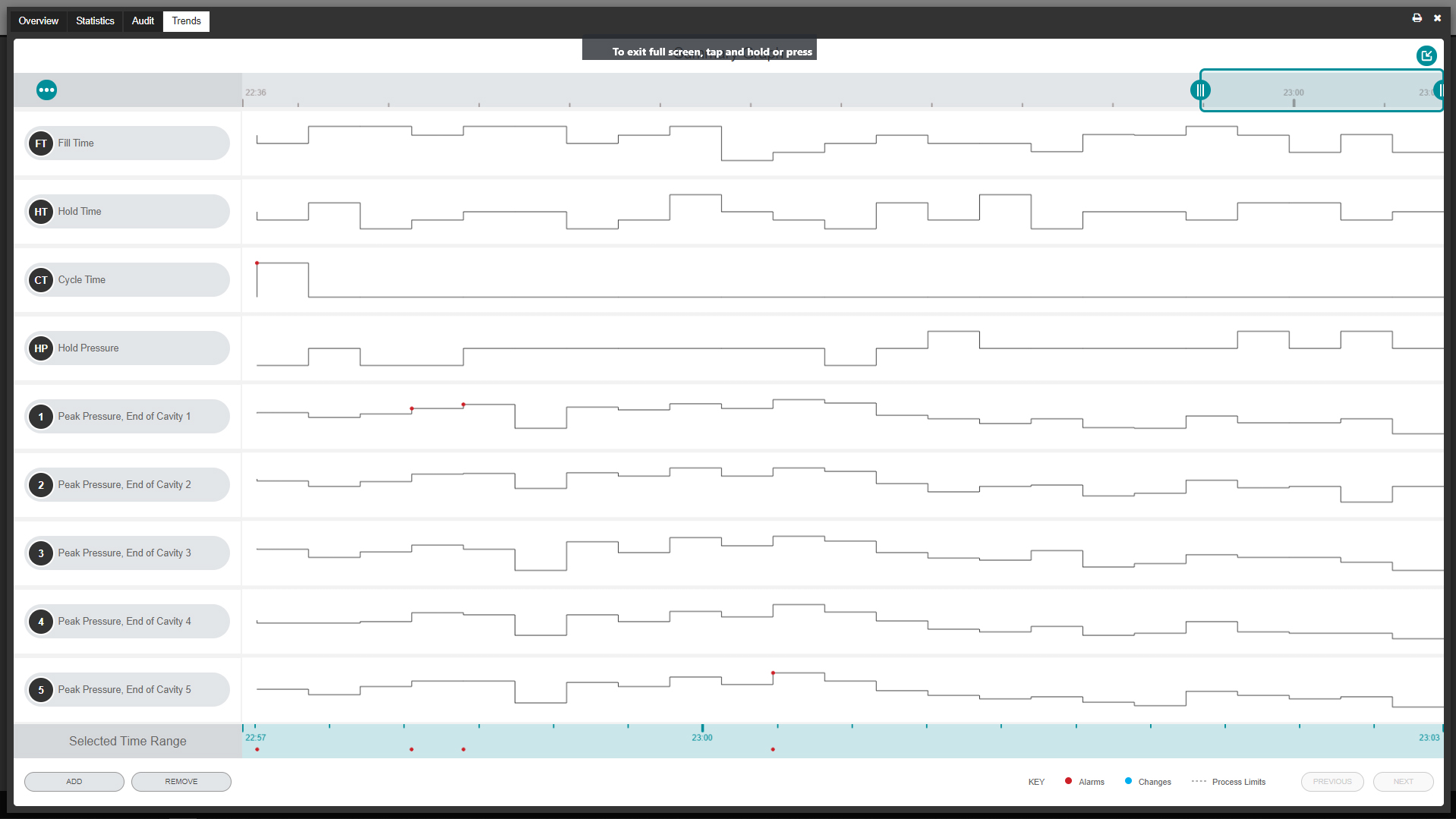

Ensure the quality of every part shipped

- Build an audit trail to prove every shot

- Review historical data on each machine

- Compare past shots to see what changed in the process

Stop manually auditing processes

- Access automated audit reports any time during or after a run

- Review historical reports

- Export reports

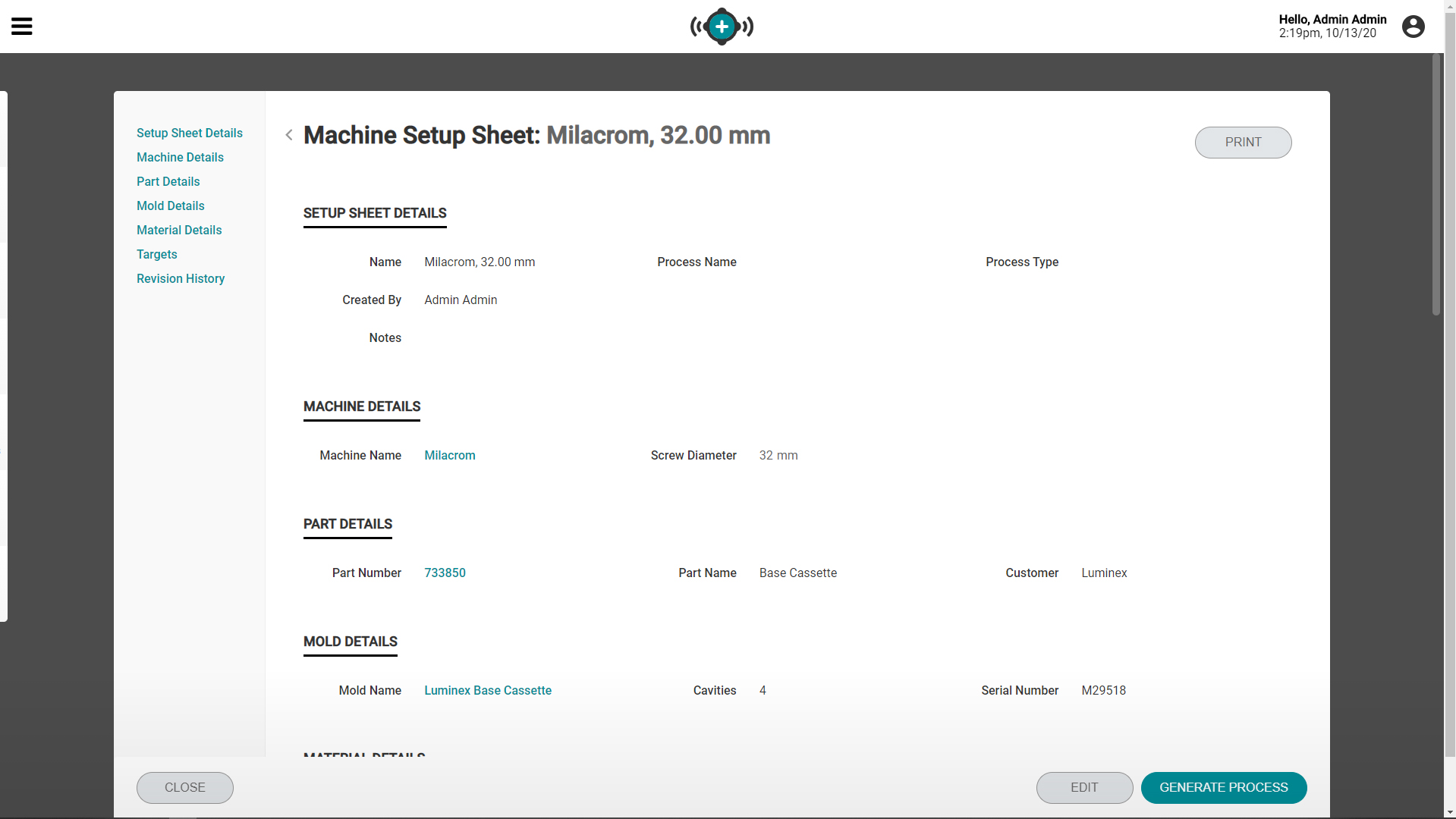

Start making better parts faster

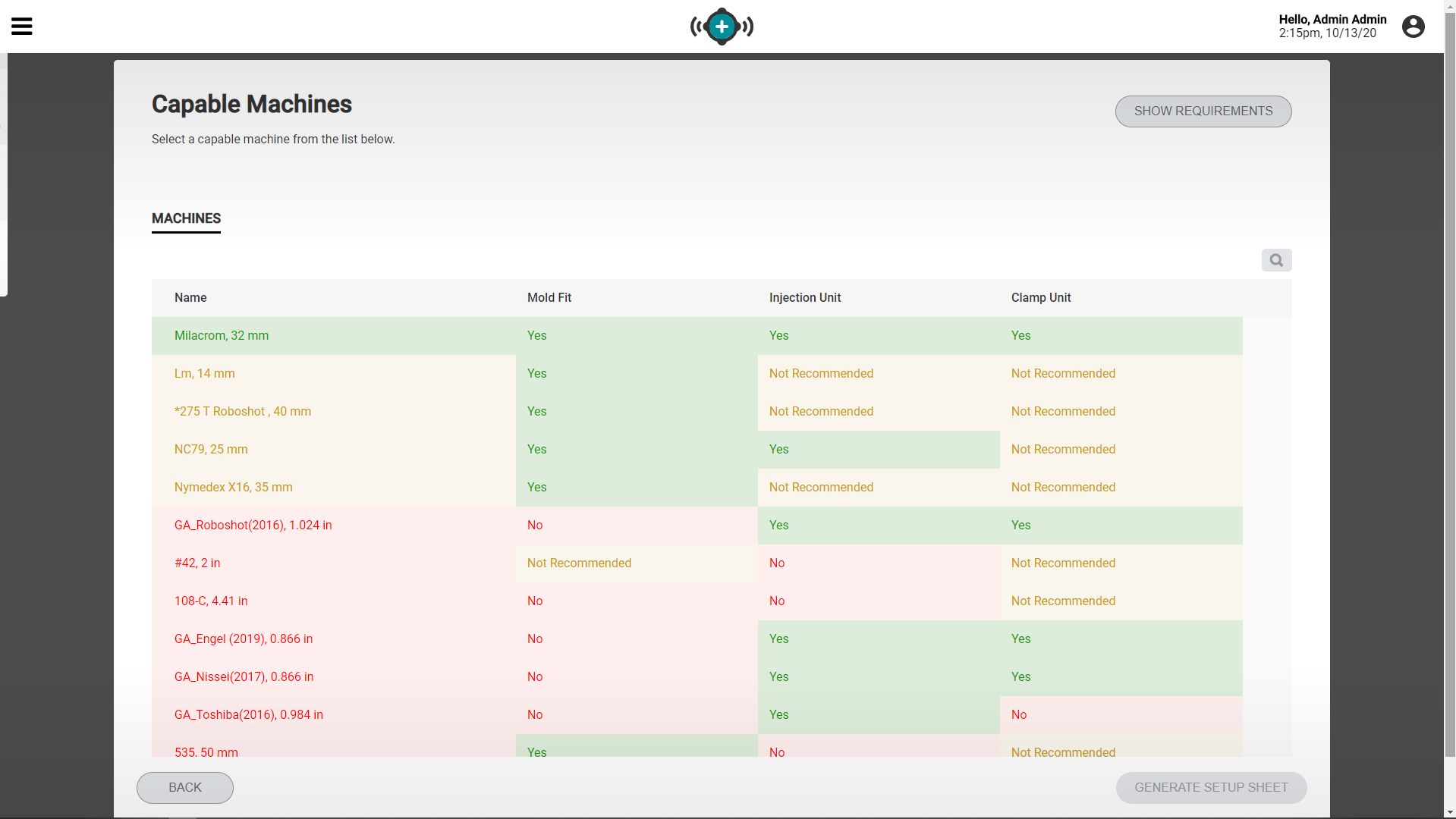

- Ensure the right mold is in the right machine

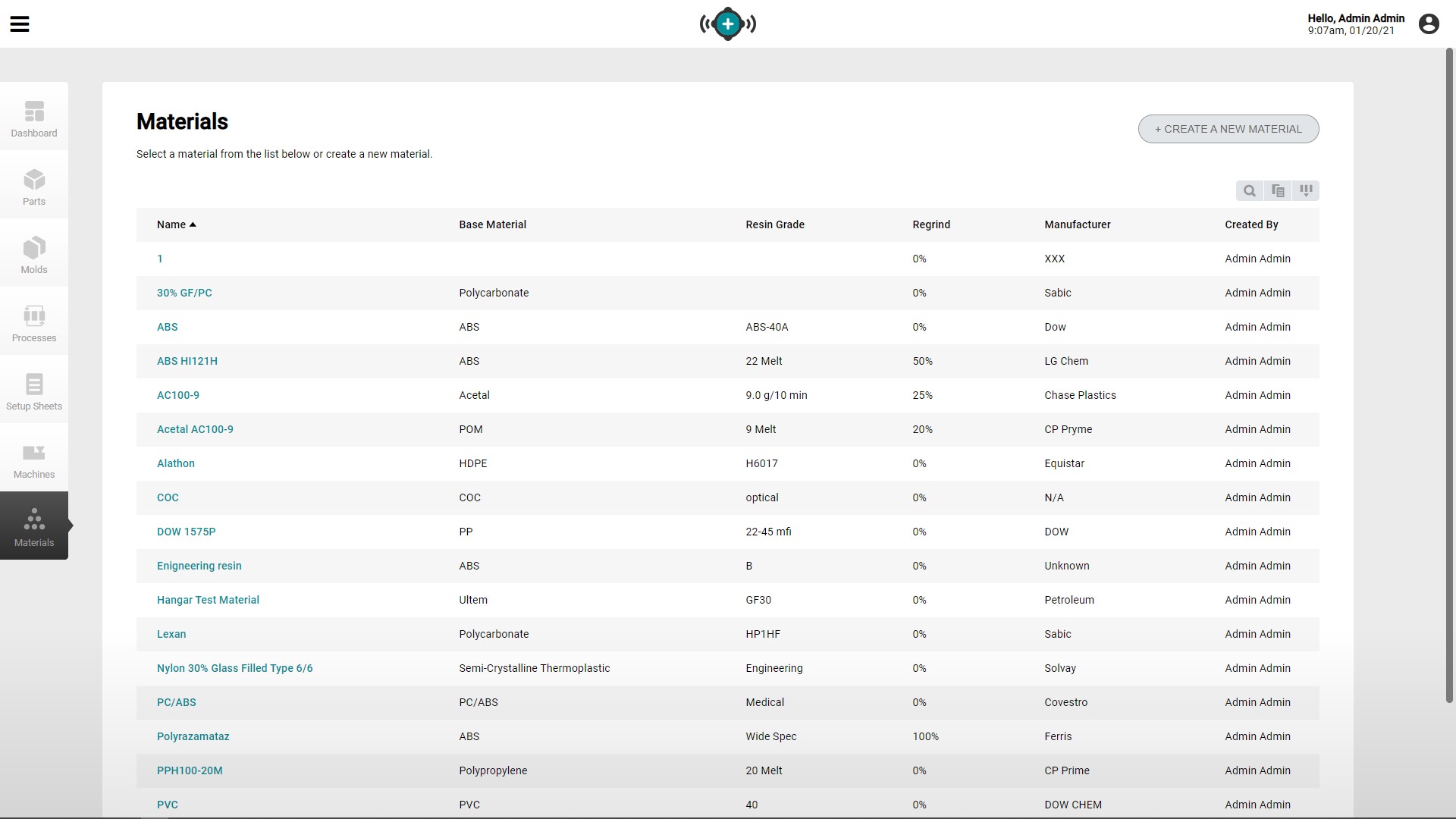

- Access all facility assets from one place

- Automatically generate machine-specific process sheets

- Easily move a mold from one machine to another

The Hub Connect: Integrate With Your ERP and MES

The Hub Connect bridges the gap between your process data and operational data, enabling you to make informed, data-driven decisions. Our cutting-edge software utilizes the OPC-UA protocol, ensuring fast and secure data extraction and integration with your existing ERP/MES systems.

Benefits of The Hub Connect:

- Improved process control - Real-time data allows you to proactively identify and address process deviations, ensuring consistent product quality and reduced scrap.

- Enhanced operational efficiency - Optimize process parameters and machine performance to reduce cycle times, improve productivity, and minimize downtime.

- Data-driven decision making - Gain valuable insights into process trends and performance patterns, enabling informed decisions to enhance production efficiency and product quality.

- Reduced costs - Minimize scrap, reduce downtime, and optimize resource utilization, leading to significant cost savings.

The Hub Lite: Fast Track from Tryout to Production

The Hub Lite, a new offering in The Hub data solutions, makes it easier than ever to capture tool tryout data and migrate it from the tool shop to the production floor, simplifying the process of collecting and distributing data and templates from tool trials. The Hub Lite features laptop portability and data exports and migration (including correlation, data runs, proof of concept, and universal setup sheets). That allows you to quickly and easily import your setup sheet right to your CoPilot and start making good parts fast.

Benefits of The Hub Lite:

- Tool builders gain a competitive advantage by providing tryout data and process templates

- Quickly and easily import tool tryout data and templates into the CoPilot

- Access data anywhere from a laptop

- Collect more accurate, reliable data on each tool

- Molders gain flexibility with tool builders by standardizing information and streamlining their process

Product documentation

Access useful information and guides for The Hub. Don't see what you need? Let us know!

Packages | ||||

|---|---|---|---|---|

Features | Hub Mold | Hub Process | Hub Sim | Hub + |

| Mold Transfer | ||||

| Facility Asset Database: Machines, Molds, Parts and Materials | ✔ | ✔ | ✔ | ✔ |

| Mold Match Recommendations for Fit and Capabilities | ✔ | ✔ | ✔ | ✔ |

| Universal Process Sheet Database | ✔ | ✔ | ✔ | ✔ |

| Machine Specific Setup Sheet Database | ✔ | ✔ | ✔ | ✔ |

| Automatically Generated Machine Specific Setup Sheet | ✔ | ✔ | ✔ | ✔ |

| Revision History | ✔ | ✔ | ✔ | ✔ |

| Process Analytics | ||||

| Historical Process Data | ✔ | ✔ | ||

| Audit Reports for Process Changes | ✔ | ✔ | ||

| Plant-Wide Summary Reports | ✔ | ✔ | ||

| Plant-Overview Dashboards | ✔ | ✔ | ||

| Process Statistics | ✔ | ✔ | ||

| Simulation Support | ||||

| Moldex3D, Moldflow Simulation File Database | ✔ | ✔ | ||

| Automatically Populated Mold Database | ✔ | ✔ | ||

| Automatically Generated Universal Process Sheet | ✔ | ✔ | ||

The Hub resources