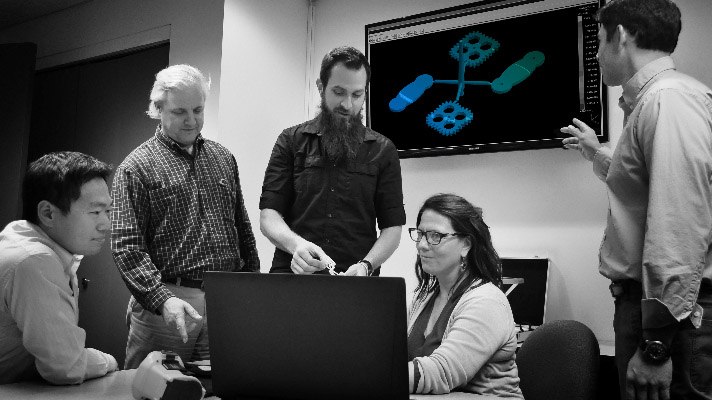

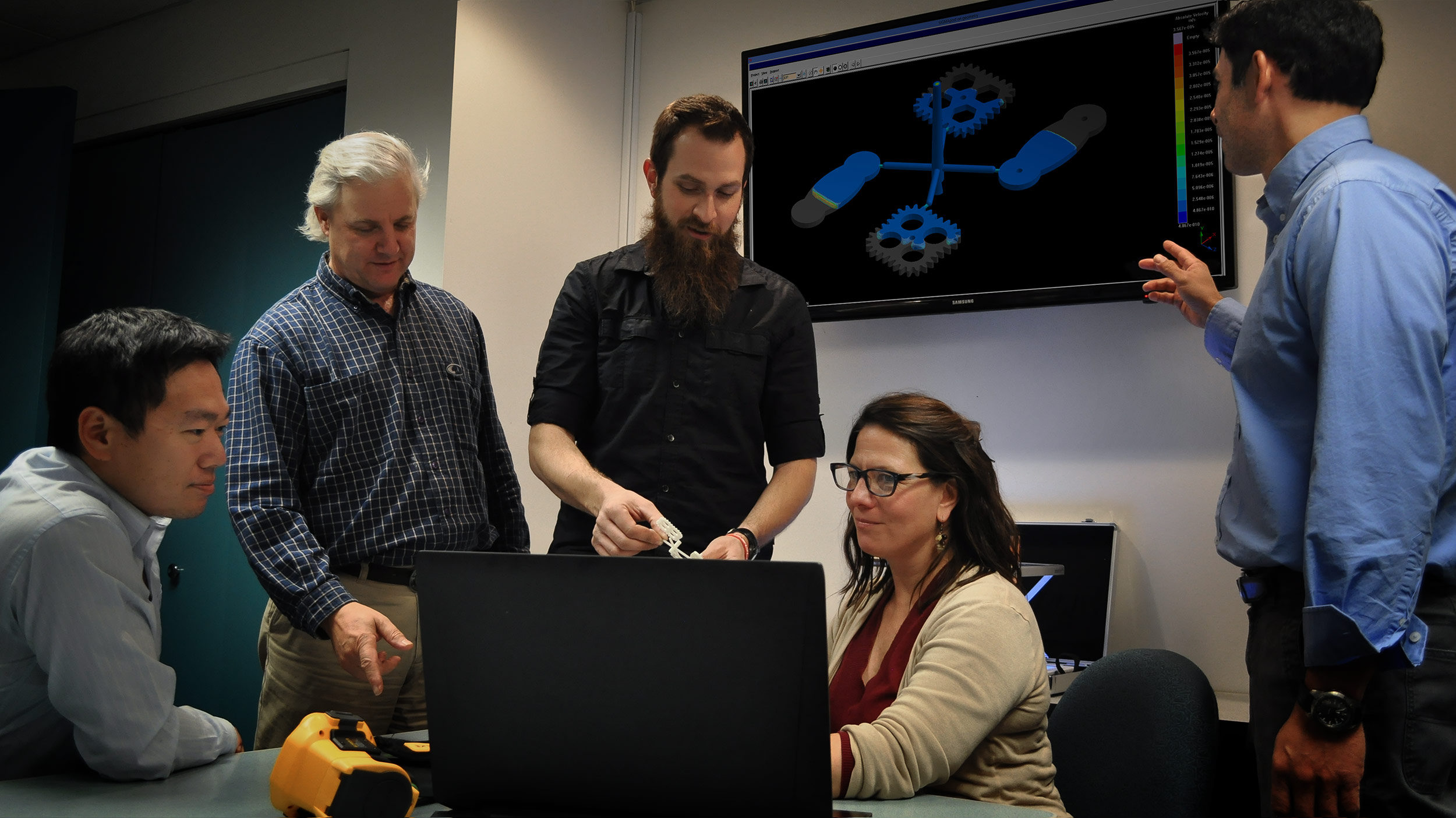

How employers save costs on tool launches with RJG

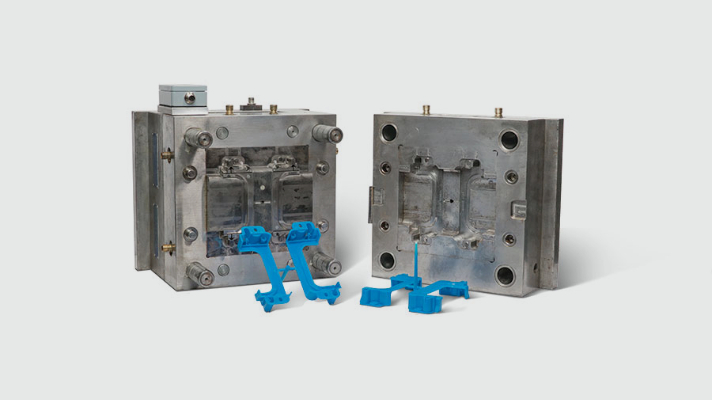

Through the combination of our TZERO program, technology, and training, employers are able to launch tools faster with much less rework. Automatically exported process setup sheets, cutting-edge simulation technologies, and industry-leading expertise allow you to make good parts from the first shot. That means substantial time and cost savings and getting a leg up on the competition.

How are we different from other solutions companies?