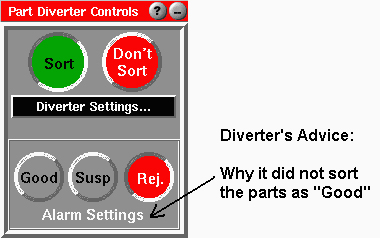

Tip of the Day 10: Listen to the Diverter’s Advice

Notice that the Diverter Controls window has a small blank spot at the bottom of the screen in which it places information about why the parts were not counted or sorted as “Good”.

Last week while supporting a customer some time was spent looking around for why the parts were rejecting until we brought up the “Diverter Controls” window and noticed that it said “Pinched Part”. Then it was easy to discover that the customer had two “Mold Opening” events on every cycle.

Therefore, if you want to know why parts are being rejected, look here first. If the part diverter shows that they are “Good” but the robot is still throwing them out then you have a robot logic or wiring issue. You can open the “Diverter Settings” menu and use the “Test” feature. Or you can check into the robot’s requirements for level v.s. edge triggering or when it actually looks at the signal.

Here is the list of all the items that can appear in the “Advice” box:

In Setup State: Production State switch at “Setup” or down state just ended.

No Alarms Tool: There is no tool running to decide if there is an alarm. Drag the “Alarm Settings” tool onto the workspace in the Architect.

No Alarms Set: In the Alarm Settings tool no alarms have been chosen.

All Alarms Off: In the Alarm Settings tool all “Sort” switches are off.

Don’t Sort Pressed: The diverter is stopped by pressing the “Don’t Sort”

Sampling Parts: The Part Sampling tool is running and sampling parts with its “Reject samples” switch turned on.

Press is Down: The press is not running. All that drops out of the mold is diverted so it doesn’t go into the good container.

Diverter in Test: The test buttons on this diverter control are in use.

Press in Manual: The press is in manual (from the sequence module input).

Match Meter: The Process Match Meter is set to sort parts and is in the yellow or red zone.

Alarm Settings: The Alarm Settings tool has one or more active alarms.

Pinched Part: The mold has opened twice indicating a part may be crushed. The eDART sees this from two “Mold Opening” signals going on in one cycle. The first is from the “real” opening when the part is attempted to be ejected. The second opening comes when the mold protect on the machine re-opens the clamp after a pinched part (before the start of the next cycle).

Note: This feature can be turned off if you have a bad “Mold Opening” signal. Better yet, make “Mold Opening” a “Not Used” in “Sensor Locations”. If it is not correct then it should not be named “Mold Opening”.

Press Not Cycled: The job has just started but the press has not cycled yet.

Queue Not Filled: The diverter delay is set up but not enough parts have yet been made to get a “good” one to the end of the queue.

This can no longer occur once Insightpro “Scrap Entry” is no longer supported:

Manual Rejects: More parts were manually rejected than made so some of the parts now being made will be rejected.