Take our free online Training Placement Questionnaire to see what course is right for you

RJG in-plant courses

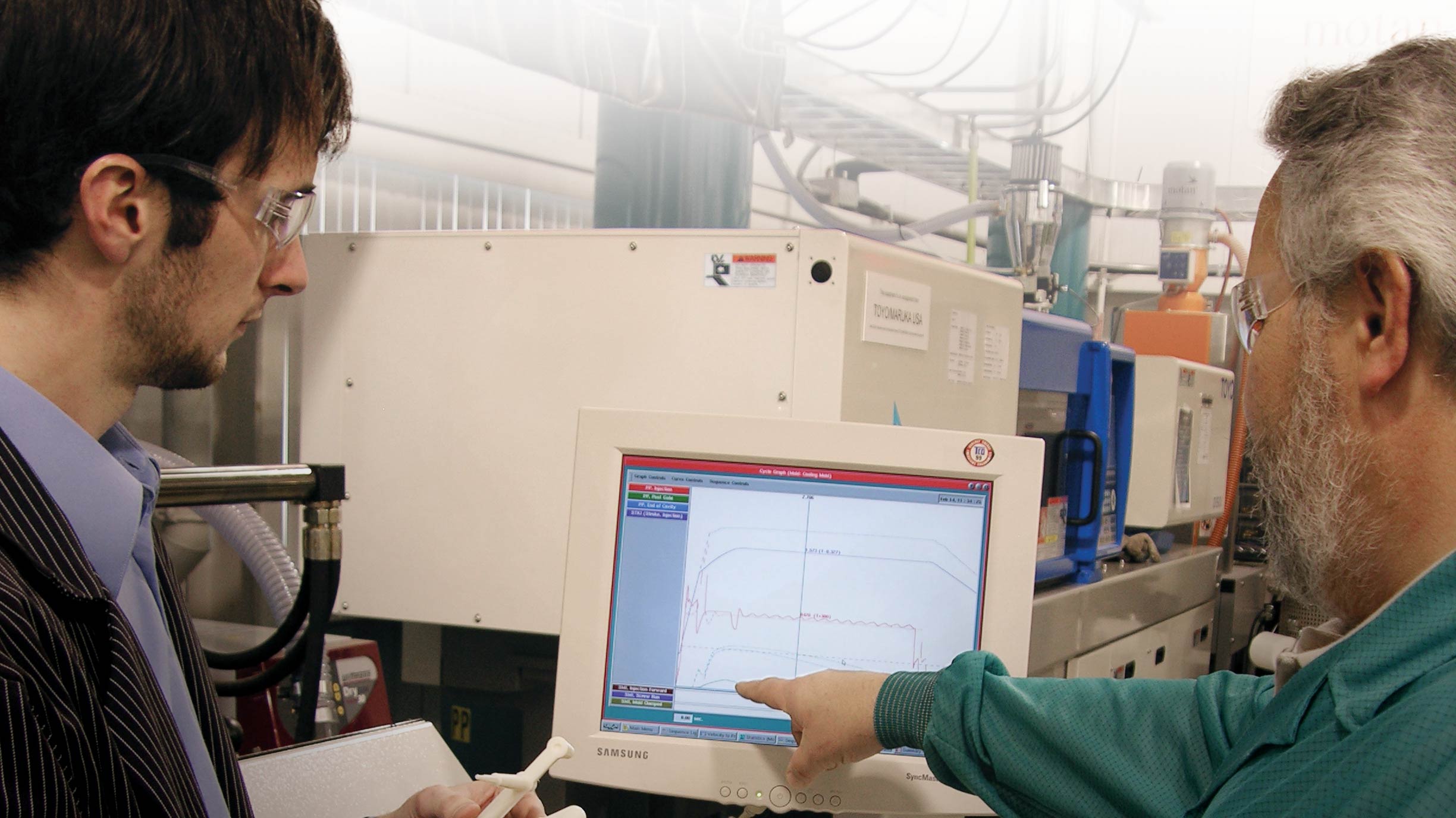

About in-plant courses

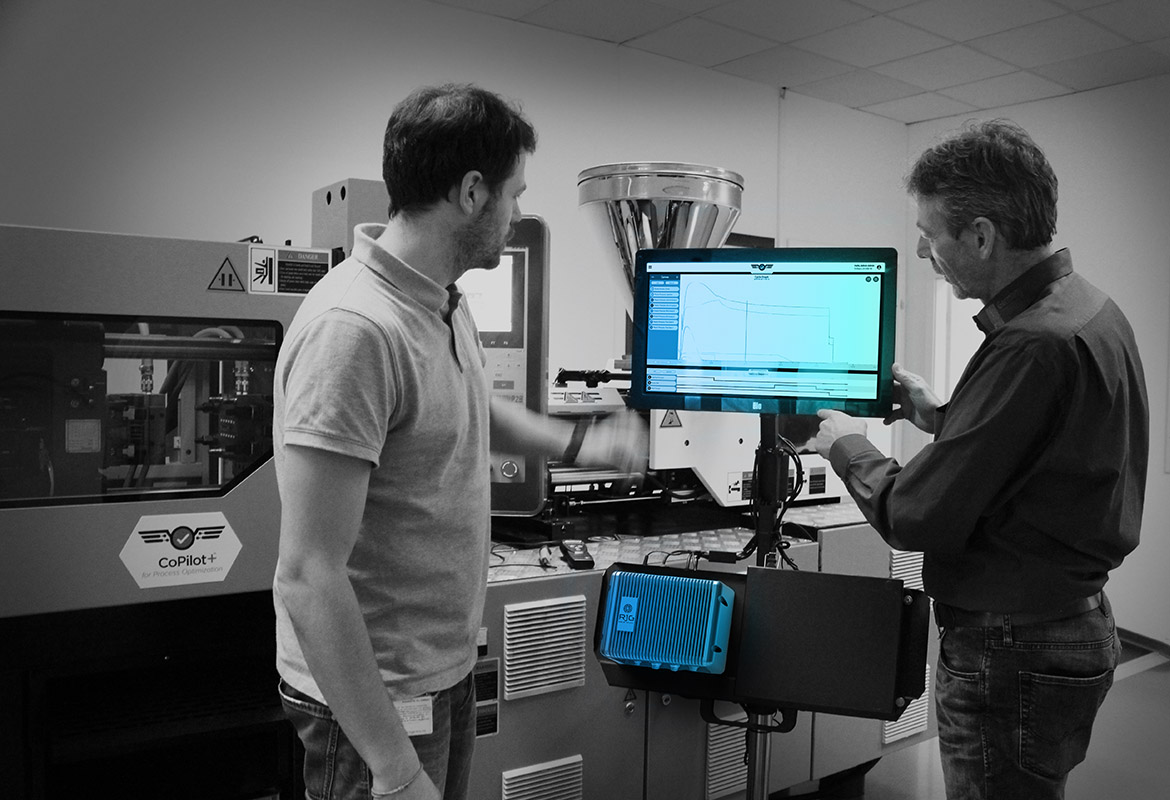

One of our expert consultants will come to your facility and train a group of your team members together. This is a cost effective way to include teams from multiple departments, as it eliminates the need for travel and extended time away from work.

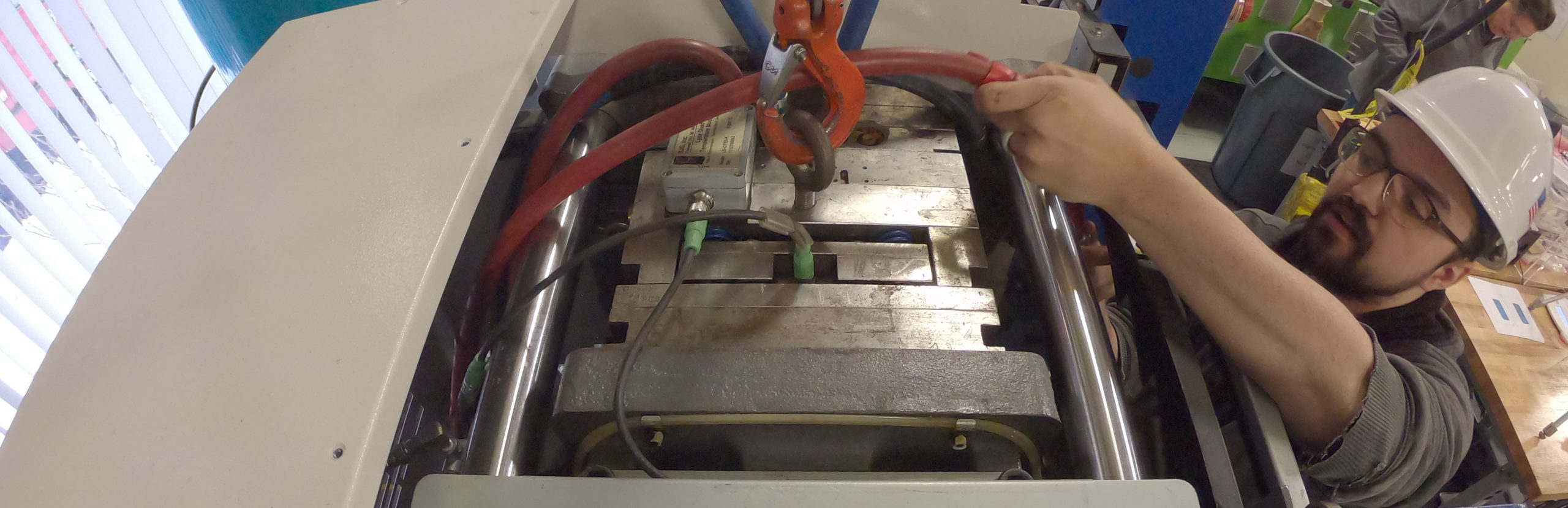

This is often an ideal method of training because you’re able to use your own machines and customize training to your specific needs. We will also create a training implementation plan to ensure your long-term success.

Benefits of in-plant training:

- Train many employees simultaneously

- Eliminate travel costs

- Reduce time away from work

- Use your own machinery and equipment

- Customized training for your specific needs

- A full training implementation plan

- Get everyone speaking the same language

How does in-plant training work?

One of our expert consultants will come to your facility to provide customized, one-on-one training to your company. Your team will walk away speaking the same processing language, which often improves organizational efficiency and communication.

Meet some of our trainers

Jacque Gibson

Trainer

Andy Nicholls

Trainer

Sean Yang

Trainer