Take our online assessment to see what course is right for you.

Helping companies achieve substantial time and cost savings with expert consulting services.

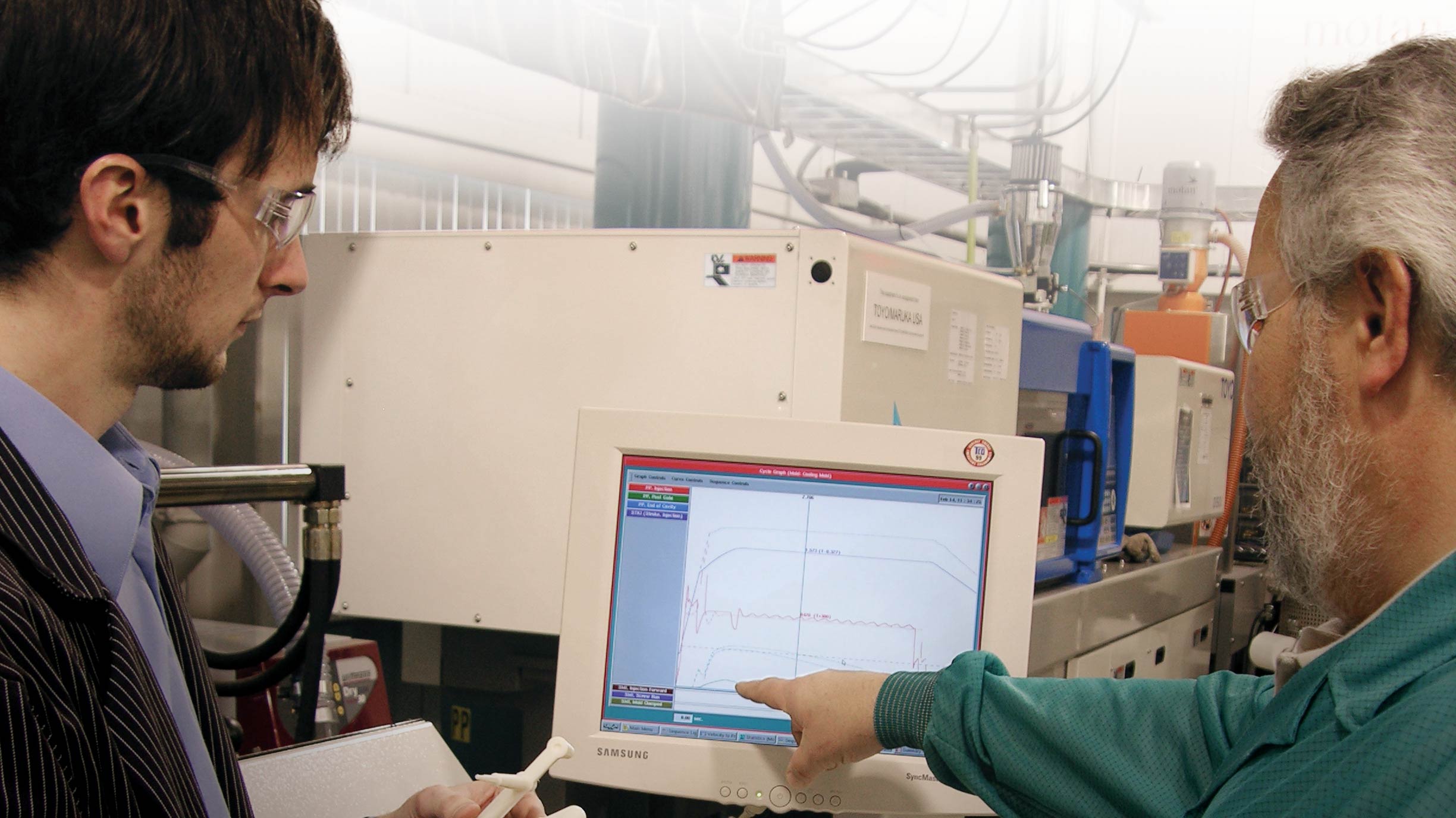

Plant Assessments to Get a Clear Picture of Current State

Uncover Hidden inefficiencies with an RJG GAP Assessment

Struggling with high scrap rates or down time? Our GAP Assessment provides a deep, data-driven analysis of your injection molding operations to identify inefficiencies, quality risks, and opportunities for improvement. We evaluate your facility, equipment, processes, and team to pinpoint areas impacting performance. Following the assessment, you’ll receive a comprehensive report with clear, actionable recommendations to enhance productivity, reduce scrap, and drive operational excellence.

Ready to elevate your manufacturing process?

TZERO Solutions to Launch Tools Faster and More Efficiently

TZERO uses a variety of software programs combined with experience to provide an end-to-end solution and ensure absolute efficiency during product launch and beyond. Our TZERO solution is based around three main areas:

Part Design Analysis: We’ll analyze your part design, geometry, and material from the processing and tooling standpoint to determine if your part is ready to be built and manufactured.

Mold Design Analysis: We’ll evaluate the design of an injection mold to ensure structural integrity and analyze the melt delivery system, venting, cooling, and ejection to ensure equipment capability.

Injection Molding Simulation: Through the use of simulation analysis, we’ll evaluate all aspects of design to identify potential molding defects and ensure proper equipment capability.

Process Consultation to Make Better, More Consistent Parts

Whether you’re looking to solve ongoing problem areas, lower cycle time, reduce scrap, or anything in between, we’ve got you covered (even if you’re not using our equipment). We focus on three main areas:

Process Optimization: Optimize your injection molding processes so that you can make high quality plastic parts more efficiently and cost effectively.

Curve Interpretation: Understand what your process curves are telling you so that you can get the most out of your equipment.

Sensor Placement Strategies: Choose the right sensor, placement, and installation method to ensure you have the tools needed upfront to make your investment count.

Meet some of our consultants

Sean Yang

Trainer

Jorge Banderas

Trainer

Bob Reese

Trainer

RJG consulting resources