Injection molding equipment is the backbone of many manufacturing operations, enabling the production of a wide range of plastic products efficiently and cost-effectively. However, like any machinery, injection molding equipment requires regular maintenance to ensure optimal performance, longevity, and safety. In this blog post, we’ll explore some essential maintenance tips to keep your injection molding equipment running smoothly and prevent costly downtime.

1. Regular Inspection

Regular inspections are key to identifying potential issues early on and preventing them from escalating into more significant problems. Schedule routine inspections of your injection molding equipment to check for signs of wear and tear, loose connections, leaks, and other issues that may affect performance. Pay close attention to critical components such as screws, barrels, nozzles, and hydraulic systems.

2. Lubrication

Proper lubrication is essential for ensuring smooth operation and preventing friction-related damage. Refer to the manufacturer’s guidelines to determine the appropriate lubricants and lubrication intervals for different components of your injection molding equipment. Over-lubrication can be as detrimental as under-lubrication, so follow the recommended guidelines carefully to avoid excess buildup and contamination.

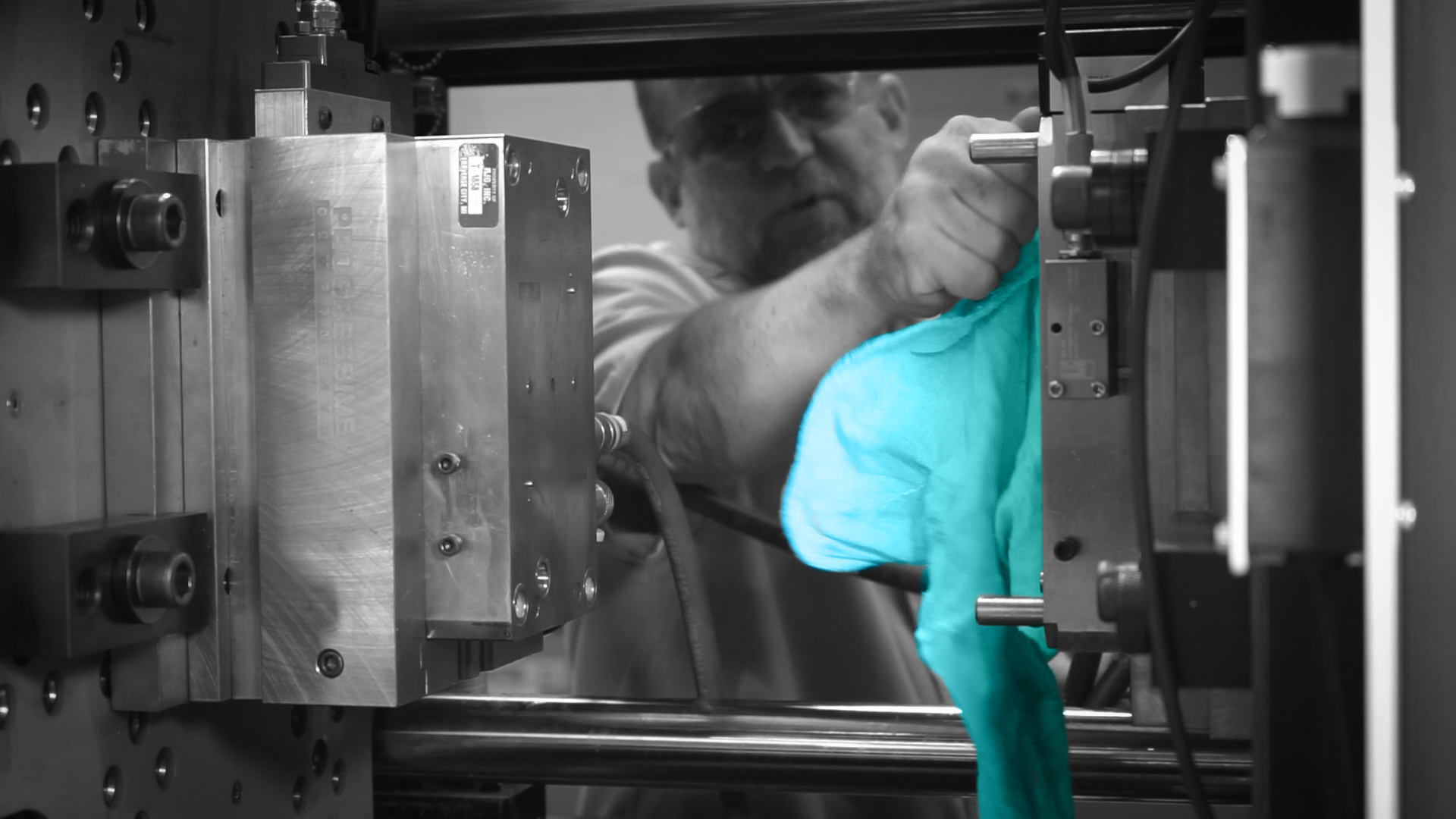

3. Cleanliness

Maintaining cleanliness is crucial for preventing contamination and ensuring the quality of molded products. Regularly clean the surfaces, molds, and components of your injection molding equipment using suitable cleaning agents and techniques. Pay particular attention to areas prone to buildup, such as cooling channels, ejector pins, and vents. Implementing a comprehensive cleaning regimen will help prolong the lifespan of your equipment and minimize the risk of defects.

Check out this video to see how to clean a mold inside of a machine.

And check out this one for tips on platen care.

4. Temperature Control

Maintaining precise temperature control is essential for achieving consistent molding results and preventing thermal degradation of materials. Calibrate and monitor the temperature settings of heating elements, molds, and cooling systems regularly to ensure they are operating within the specified range. Periodically inspect and clean heating elements, thermocouples, and temperature sensors to maintain accuracy and reliability.

5. Replace Worn Components

Over time, components of injection molding equipment may wear out or become damaged due to prolonged use. Keep an inventory of spare parts and regularly replace worn or damaged components to prevent unexpected breakdowns and downtime. Components such as seals, O-rings, nozzles, and heating elements should be replaced as part of routine maintenance to ensure optimal performance and reliability.

Check out this video on how to size a nozzle tip.

6. Operator Training

Invest in comprehensive training programs for operators and maintenance personnel to ensure they understand the proper operation and maintenance procedures for injection molding equipment. Empower your team with the knowledge and skills they need to identify potential issues, perform routine maintenance tasks, and troubleshoot common problems effectively. Regular training sessions will help instill a culture of safety, efficiency, and accountability within your organization.

Conclusion

By following these maintenance tips diligently, you can extend the lifespan of your injection molding equipment, minimize downtime, and maximize productivity. Remember that proactive maintenance is always more cost-effective than reactive repairs, so prioritize regular inspections and preventive maintenance tasks. With proper care and attention, your injection molding equipment will continue to deliver high-quality results and contribute to the success of your manufacturing operations.