Tip of the Day 88: Using the Process Match Meter to Monitor Machine Setups

You can use the Process Match Meter tool on the eDART to look for machine setup changes even when you have no pressure sensors in a mold. This match number gets displayed by the eDART Data Manager on the “Advanced System Overview” web page. Thus you can see at a glance whether all of the machines have been set to their standard process.

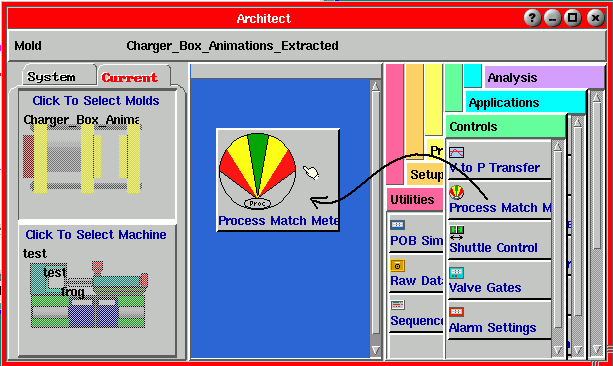

Step 1: Drag the Process Match Meter onto the Architect’s workspace. If you want to “attach” the meter to all molds click the “eDART System / Molds” folder under the Architect’s “System” tab and drag it there.

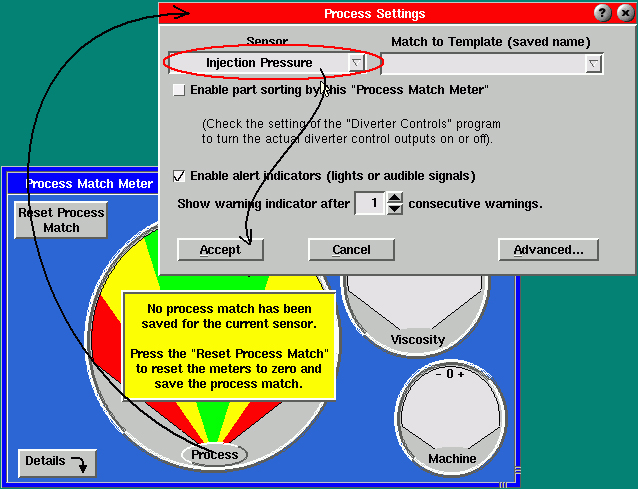

Step 2: On the Process Match Meter click the “Process” tab, select the “Injection Pressure” sensor and then click “Accept”.

Step 3: Stabilize the process. Always make process matches after the process has been running long enough to become stable.

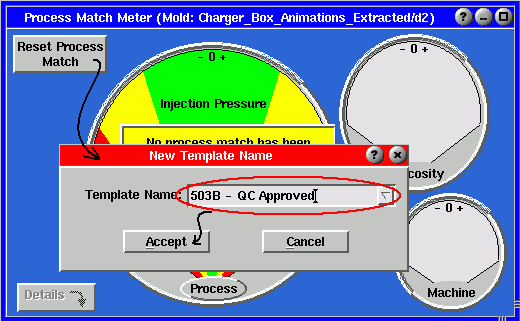

Step 4: Click “Reset Process Match”, enter a new match (and template) name and click accept.

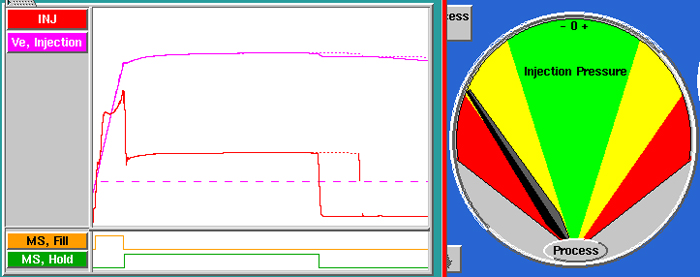

The meter will make a template and a match file at the end of the current cycle. It then begins to match the injection pressure to the match file on every shot. It computes a number for the match that the Advanced System Overview (ASO) displays on any office web browser as a moving bar. Also the meter needle moves in sync with the number on the ASO.

Note that the injection pressure curve will vary with viscosity as well as with changes in machine setup. We will be improving this at a later date. At this time you could make a machine setup match for each significantly different viscosity material (say “Low”, “Medium” and “High”).

If the match meter needle goes off center look at the cycle graph to see the cause. You can’t tell without a Post Gate cavity sensor but the gate may not be sealed any more and this could cause sink at the gate.

You can also make a process match by machine / process combination as described for templates in Tip # 87. The name I chose here reflects this.

Notes for the future:

We expect to release improvements in the process match with eDART software release 8.6 (summer, 2008). This version will automatically compute template matches for both machine and in-cavity process values whether the Process Match Meter is running or not. Thus you will not have a “match” file separate from templates. Whether an eDART is using the match meter or just the cycle graph the ASO will always display a match indicator as long as a template is active.

Also the new “Setup Match” (machine setup) will match the speed profile template (volume) until transfer and then injection pressure until the end of the cycle. Furthermore it will always make a “Setup Match” for the machine curves and a “Process Match” for the in-cavity curves.

Historical note:

When the Process Match Meter was created in December, 1999 the eDART Cycle Graph did not have a template. Or at least it did not share it. So the meter had to make its own match file. Now that the match concept has become part of the Advanced System Overview we plan to bring the two together.