Fluid dynamics is a fancy word for understanding the behavior of different types of fluids, which is essential if you want to fully control your injection molding process. Before we dive too far into this area, we are going to consult our old friend, the dictionary. We need to make sure everyone has the same understanding of the definitions to the terms we are going to be discussing.

A Few Definitions

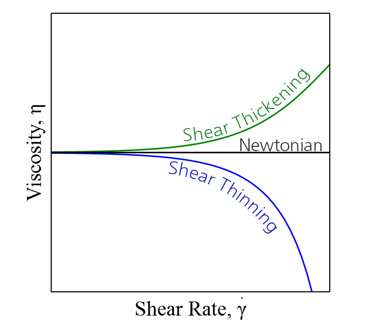

Fluid dynamics: The properties of fluids in motion. There are two different types of fluids: Newtonian and Non-Newtonian (Shear Thickening or Shear Thinning) along with understanding viscosity as shown in the graph below.

Viscosity: The resistance to flow. The more the fluid resists flow, the higher the viscosity.

Shear rate: The change in velocity of parallel planes in a flowing fluid. Picture a river and how the water flows differently near shore in comparison to in the center of the river. At the edges, the water flows slower. That’s why the fish hang out there, because they don’t have to work as hard to stay in one location. Out in the center of the river, water flows faster and has higher shear rates.

3 Types of Fluids

Now that we have that out of the way, let’s look at three common fluids within the plastics industry:

1. Newtonian Fluid: Oil

First, we will focus on a Newtonian fluid, like hydraulic oil, which is used to create linear or rotary movement on the machine or mold. If you have ever worked on a car, you may have noticed some oils flow easily while others not so much. The oil that is used in the motor is typically 5W-30. The 5 denotes the weight of the oil, which correlates to the viscosity. Lower weight equates to lower viscosity, which means it flows easier. Oils that are used in the rear differential are typically 75W-90. These oils have a viscosity 15 times higher than oil used in the motor. The motor oil will typically flow relatively easily from the container, while the rear differential oil needs to have the bottle squeezed to make it flow.

2. Newtonian Fluid: Water

Another Newtonian fluid is water, typically used to control the temperature of the mold. If the temperature changes for either water or oil, the viscosity will change as well. However, the line will still be plotted across the graph from left to right—it will just be shifted up or down based on the direction of temperature change.

No matter how fast the fluid moves, (Shear Rate) the viscosity will never change in a Newtonian fluid. This is why the rear differential oil requires the bottle to be squeezed the entire time.

3. Non-Newtonian Fluids

Now, let’s focus on Non-Newtonian fluids, specifically Shear Thinning fluids, like ketchup and plastic. Wait, what? I thought we were discussing plastics. Let me explain.

For those who have ever used a glass ketchup bottle (Figure 4), you may have seen the correlation with plastic without knowing it. If we removed the lid and turned the bottle upside down, not much would happen on its own. If we pounded the bottom really hard or inserted a knife, the ketchup would pour onto the plate. Personally, I always ended up with enough ketchup for myself and my 20 cousins at the family reunion. Tapping firmly on the 57 (the correct method), the ketchup would then flow at a more desired rate. Before doing any of the previous mentioned methods, the ketchup molecules were all entangled with each other, like a plate of spaghetti. They refused to flow in a timely manner. By applying a force, these molecules started to align, reducing the viscosity and allowing the ketchup to flow from the bottle.

Shear Rate

With melted plastics, the same type of behavior is exhibited in the barrel after the pellets have transitioned from solid to liquid form. The faster the flow rate of the machine (Shear Rate), the lower the viscosity becomes because there is more alignment of the plastic molecules.

There are always limitations and plastics are not exempt from this. Every plastic has a Shear Rate limit and we must take that into consideration when designing the mold and selecting a flow rate for the molding process. Also, materials fall into viscosity categories like the way oils are classified.

Measuring Viscosity

The viscosity of the plastic within the cavity is always changing due to different shapes and thickness and is constantly being cooled by the mold. To measure the viscosity in the molding process, we use the following formula:

Effective Viscosity = Fill Time (seconds) x Pressure at Transfer (PSIp)

This allows us to track viscosity shifts from cycle to cycle as well as from lot to lot. By understanding the viscosity of the resin under given conditions, we can predict what type of part quality will be produced.

Quite often, molders will indicate viscosity in much simpler terms, like: it flows like water, pushes like a truckload of bricks, or (my personal favorite) moves like molasses in January.

Conclusion

Fluid dynamics is only one of six injection molding areas you need to master to become a plastics pro. Learn all of them in our latest white paper.