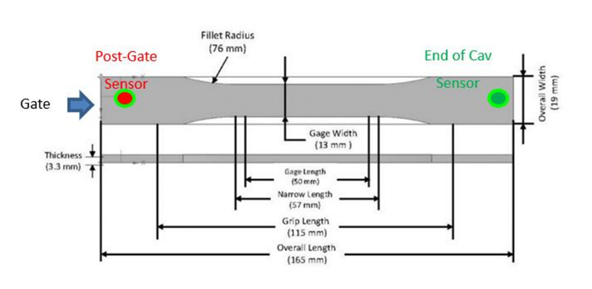

We recently collaborated with Polyplastics in order to run a series of tensile bar samples using an instrumented mold. The tensile bar is an industry standard bar that is used to run material samples and then a series of ASTM (American Society for Testing and Materials) standardized mechanical tests are ran on the bars.

This project was unique in that the mold was equipped with post gate and end of cavity sensors and an in-cavity thermocouple. We ran a small sample of 10 bars using DECOUPLED MOLDING® II and III processes in order to determine the repeatability of each process technique.

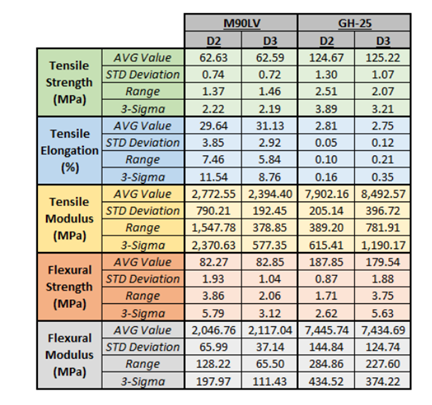

These tests consisted of:

-

Tensile strength

-

Tensile elongation

-

Tensile modulus

-

Flexural modulus

In almost all of the tests, the Decoupled III process gave a smaller range and lower standard deviation than Decoupled II. This is in line with what we have proven to be true over and over again: that Decoupled III processes minimize part variation by controlling internal cavity pressures. Decoupled III processing is a technique that uses cavity pressure to control the packing and transfer the machine to hold once a set cavity pressure using a process control system (such as CoPilot®).

We will be running a much larger sample this spring to further prove this theory. Until then, we are testing the waters to see if this is a service that would be useful to offer our clients. Would you be interested in tensile bar samples produced in fully instrumented molds? If so, let us know!