Give your company the potential for zero defect molding

Your competitive advantage begins with complete process control

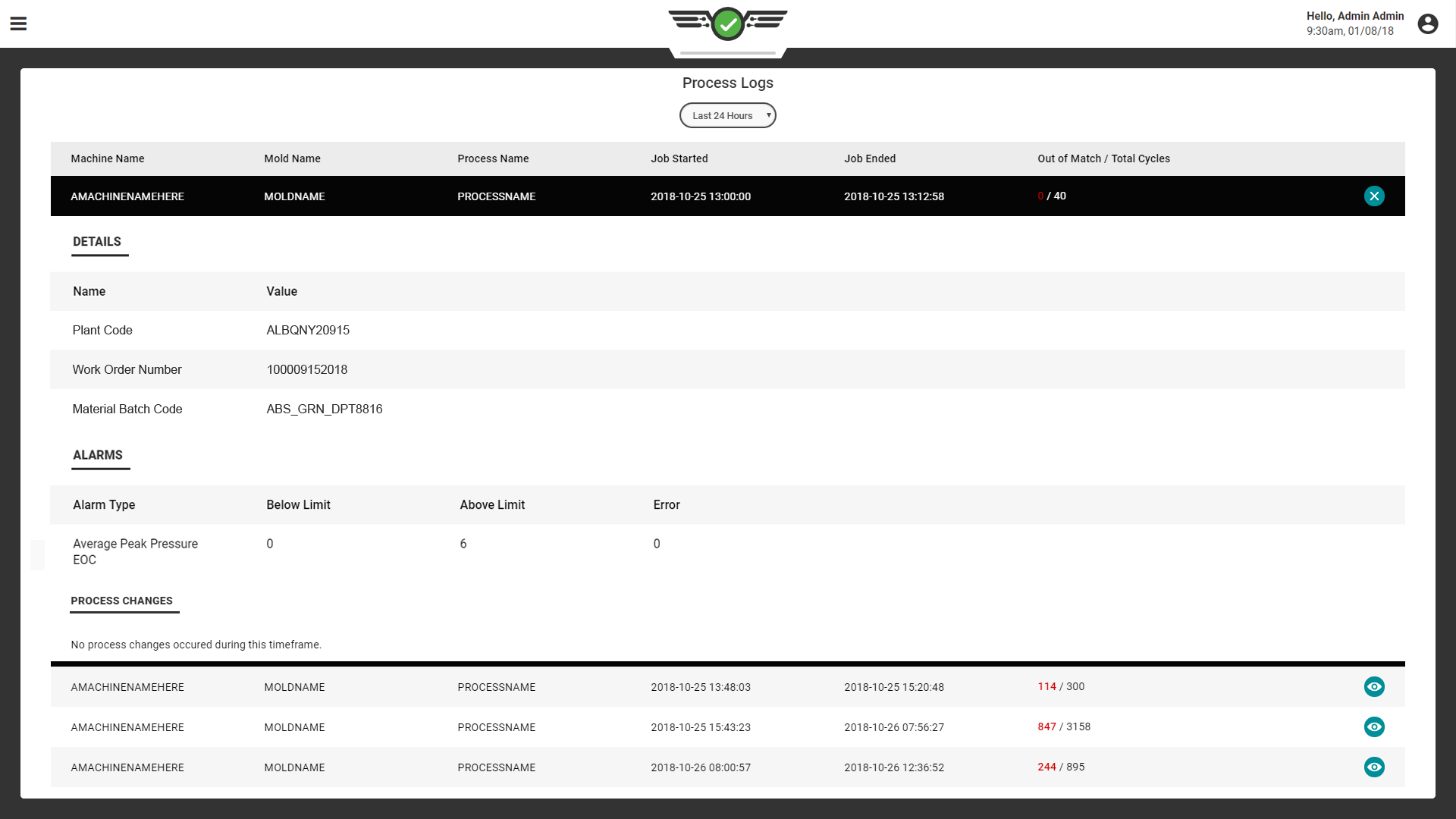

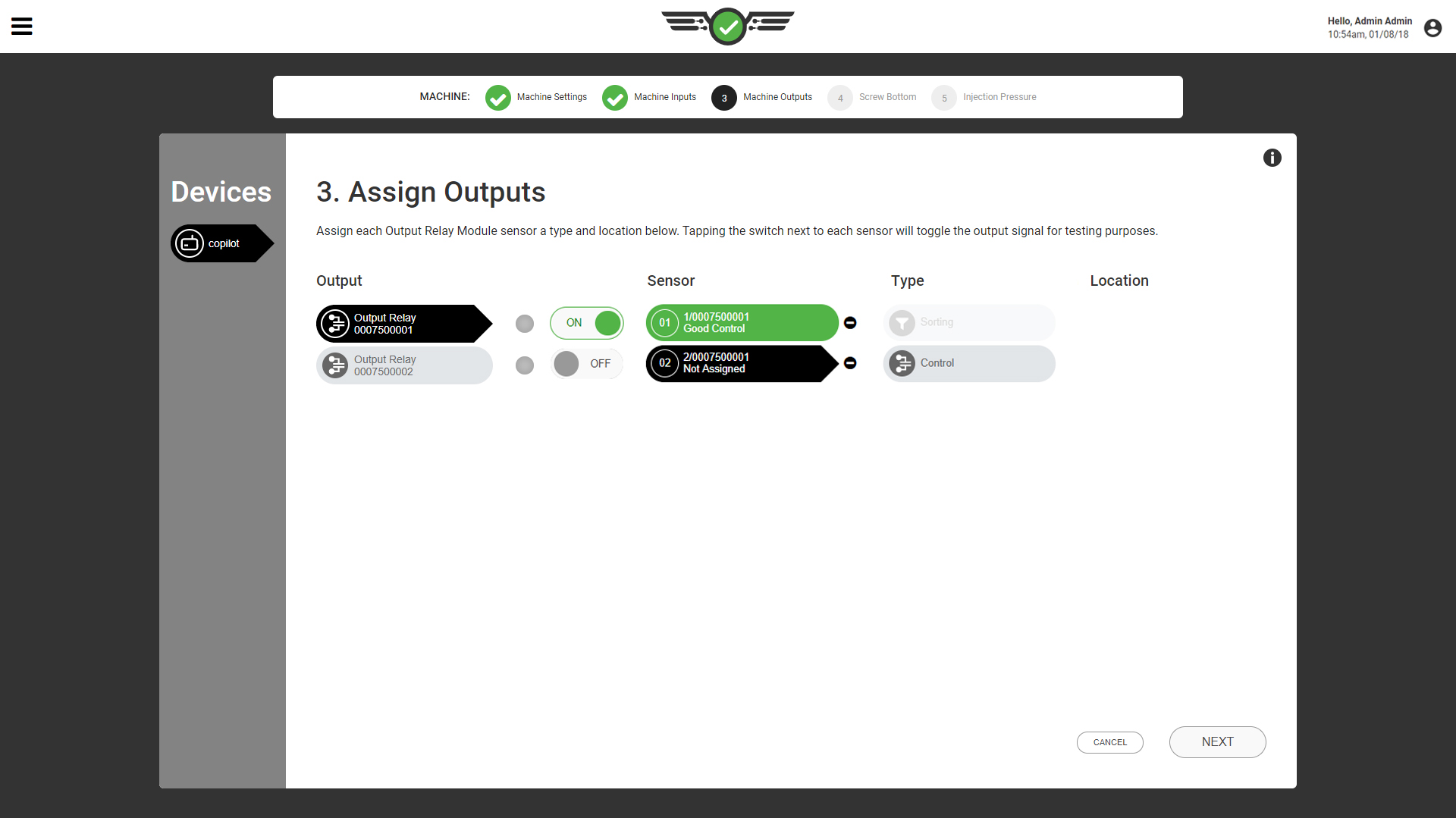

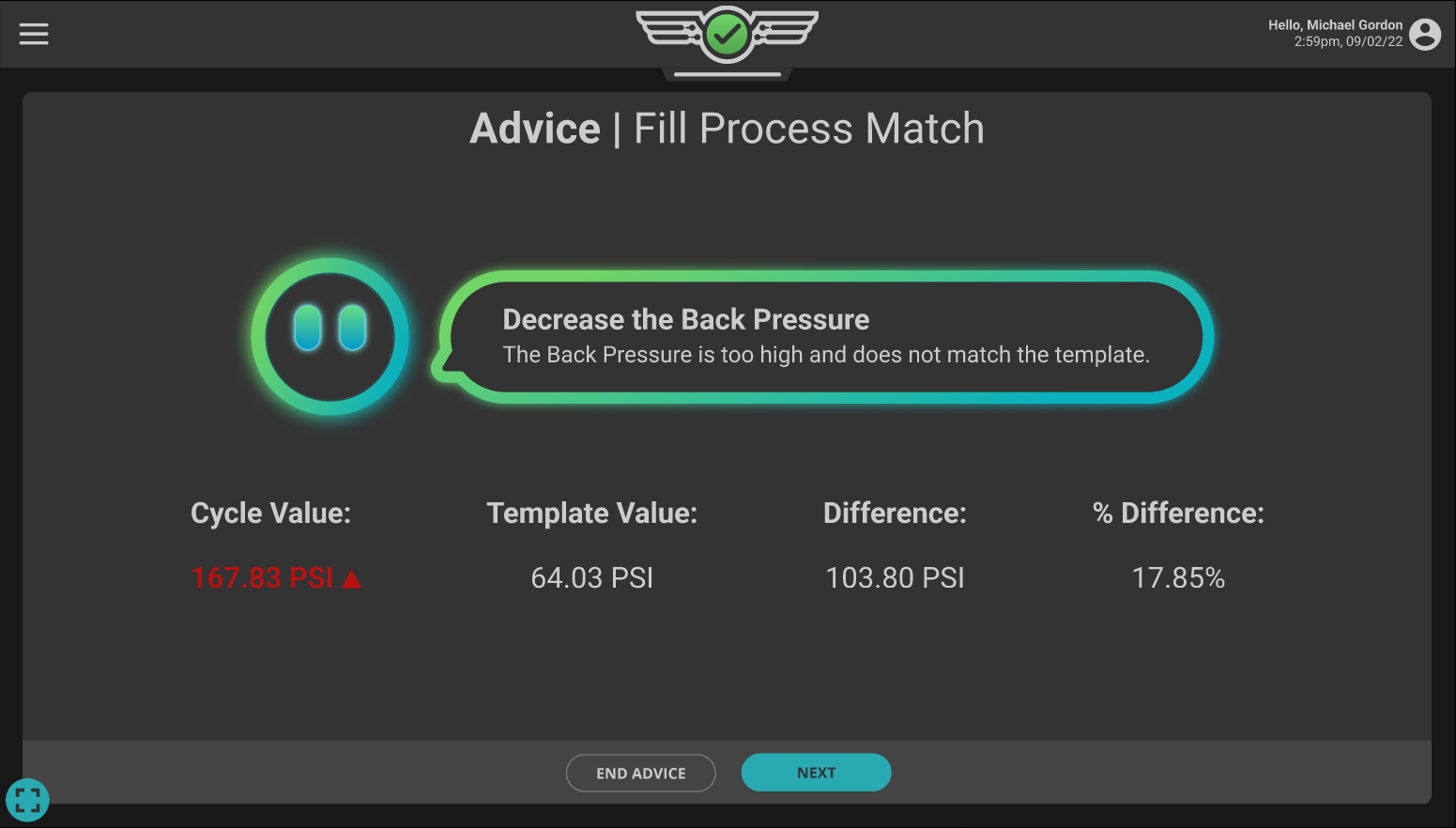

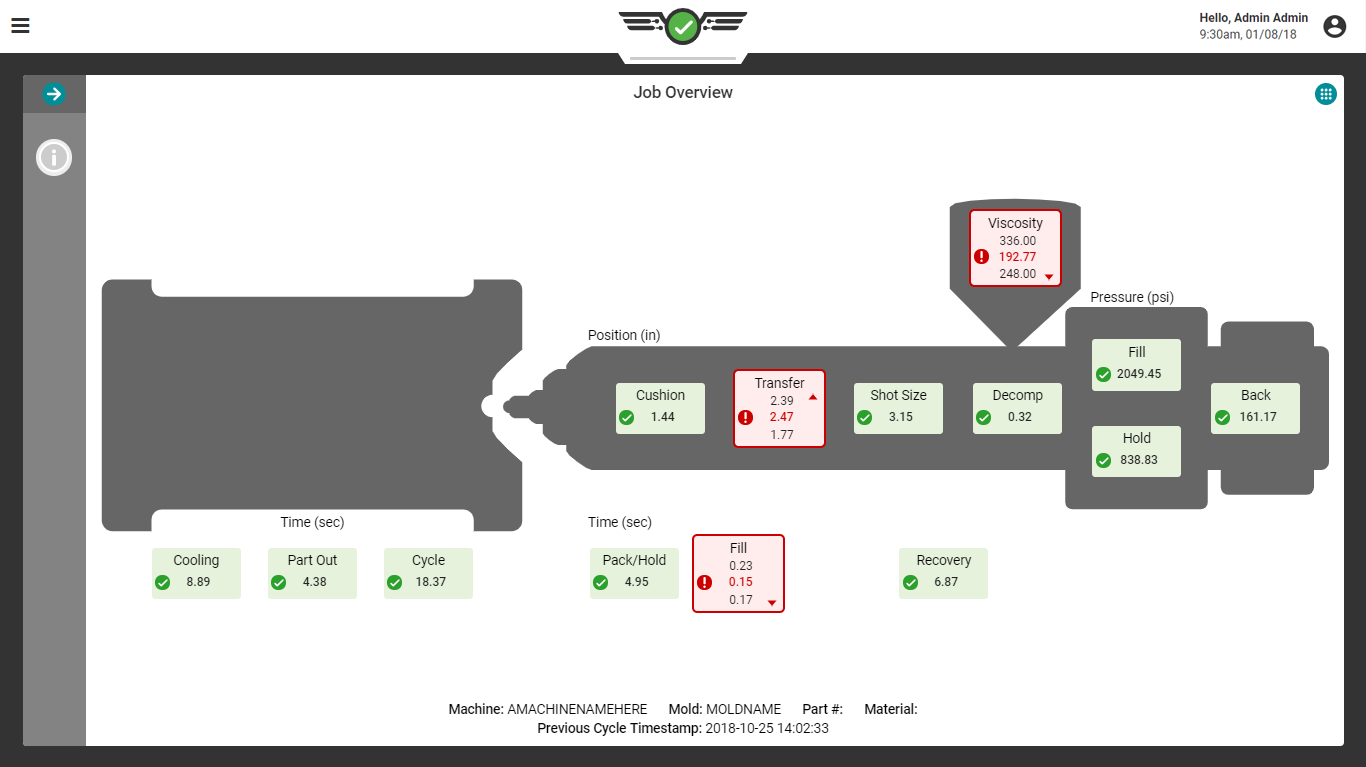

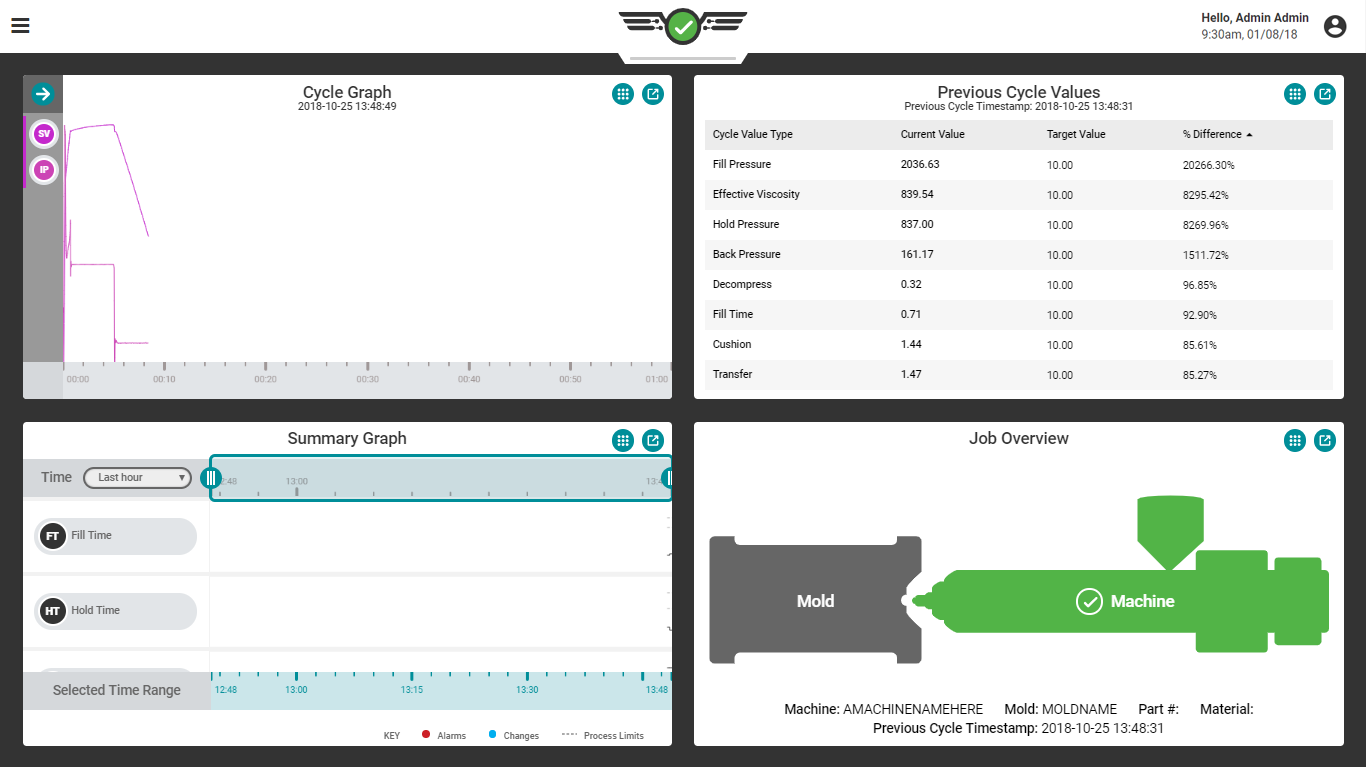

Injection molding process control software allows you to see what’s happening inside the machine and mold, know the quality of the product, understand what is changing from shot to shot, and optimize your process. This opens up the door for countless benefits, including improved part quality, reduced scrap, faster cycle times, increased output, higher revenue, and more.

Know what’s happening in the mold

• View data from each shot • Easily find where the problem • Speed up troubleshooting and downImprove quality

• Gain consistent part quality • Build templates for process matching • Reduce effects of material variationEnsure efficiency

• Ensure consistency across the globe • Reduce risk of human error • Retain parts to reduce the risk of shipping bad partsReal-time notifications

• Know the moment a process changes • Reduce machine downtime • Lower waste and make good parts again fastProduct documentation

Access useful information and guides for the CoPilot system. Don't see what you need? Let us know!