OVERVIEW

Get to market faster with TZERO®

Watch this introductory webinar to learn what TZERO can do to improve your business outcomes.

TECHNOLOGY

We have invested many years and resources into creating a correlation between sensor data and molding simulations. As a result, we developed a patent-pending methodology to transfer predicted cavity pressure and temperature settings to our process control systems.

Benefits

- Offers a better comparison between test methodology and real-world molding applications

- Used in conjunction to improve simulation accuracy, not as a replacement of standard testing

- Reduces the need for material characterization, allowing for significant time savings

In-mold rheology should be considered if your project includes one of more of the following:

Tight tolerances or narrow validation windows

Material does not exist in the simulation database

Material characterization

file is outdated

Material contains regrinds, colorant, or other fillers that are likely not characterized

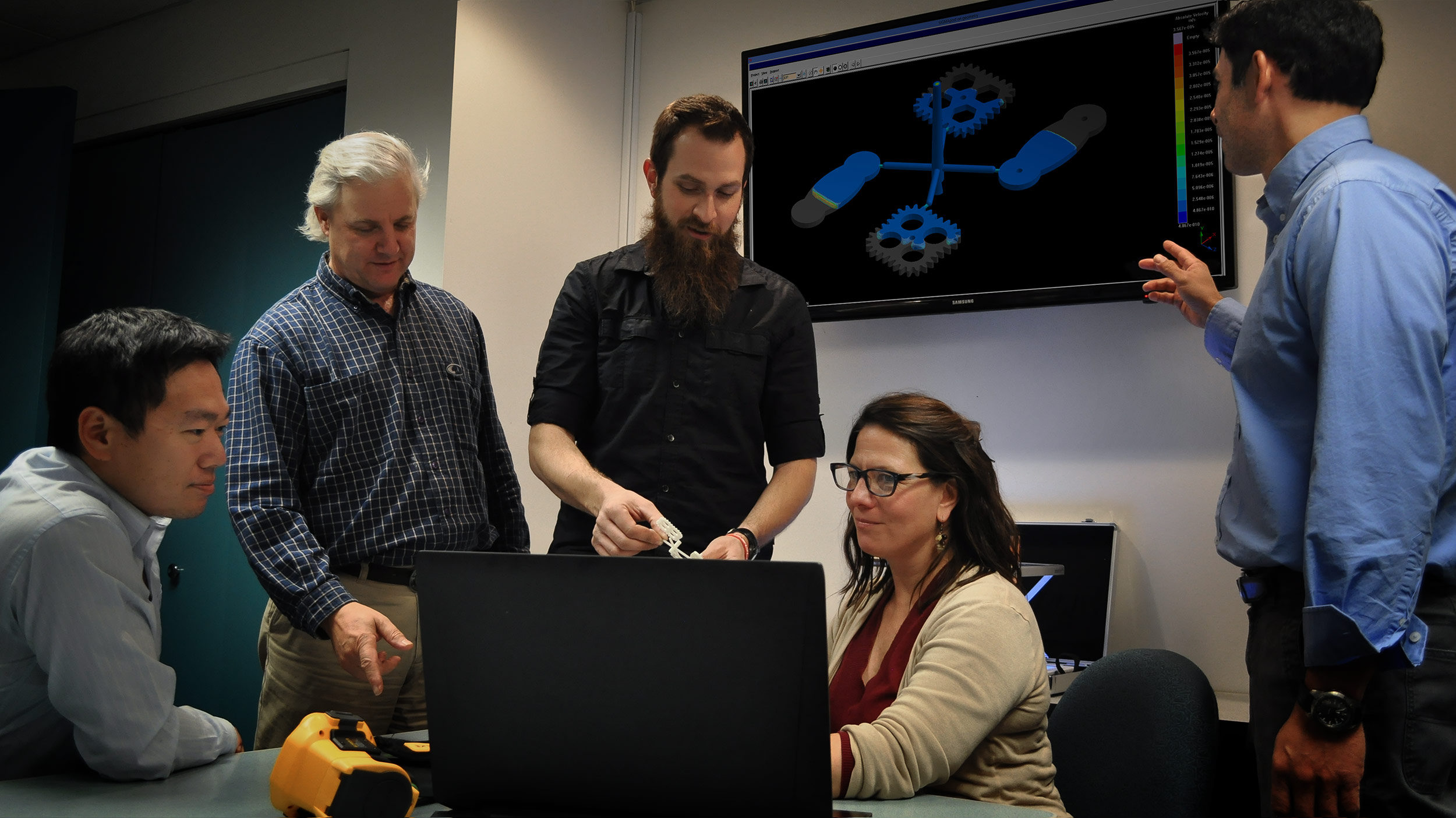

CONSULTING

Through our unique combination of experience and technology, we are able to increase simulation predictability and build processes before the steel is cut. That means making good parts from the first shot with minimal rework or wasted time.

Our Approaches

We exercise unique approaches to tool launches including:

Patent-Pending Screw Moving Boundary

Screw Moving Boundary uses the existing building blocks of simulation to model the injection unit and apply screw movement, just like a real-world injection molding process. This method is particularly effective to simulate sequential valve gates or large compressibility effects that occur in the feeding system.

Screw Moving Boundary helps to predict true injection pressure of the machine (as opposed to pressure loss), range of the barrel size, and the stroke position setting of valve gate opening and closing. It also improves the accuracy of cavity pressure prediction and clamp force requirements of the machine. The results of the simulation are later used to evaluate the appropriateness of your machine using The Hub.

This patent-pending approach was developed and validated within RJG.

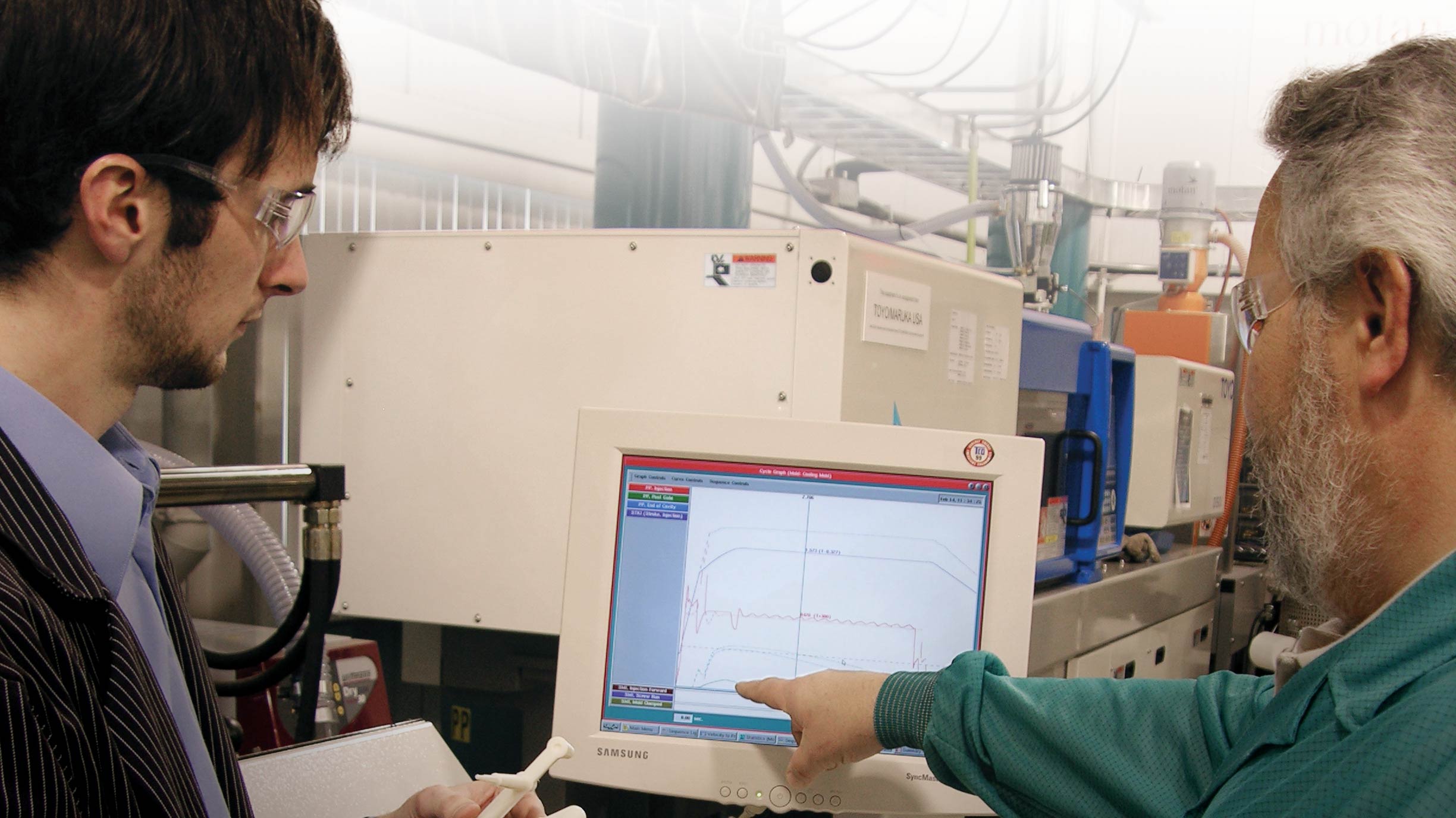

Predictive Template Transfer

We have invested many years and resources into creating a correlation between sensor measurement data and molding simulations. As a result, we developed this patent-pending method, which enables users to transfer the predicted cavity pressure and temperature to the eDART® system. This can be done at the tryout event, speeding up process development.

Once the template is matched as closely as possible, the deviation between the predicted and final templates can be quantified, and relevant influential factors can be studied. Predicted template transfer also allows users to correlate the material parameters used in simulation.

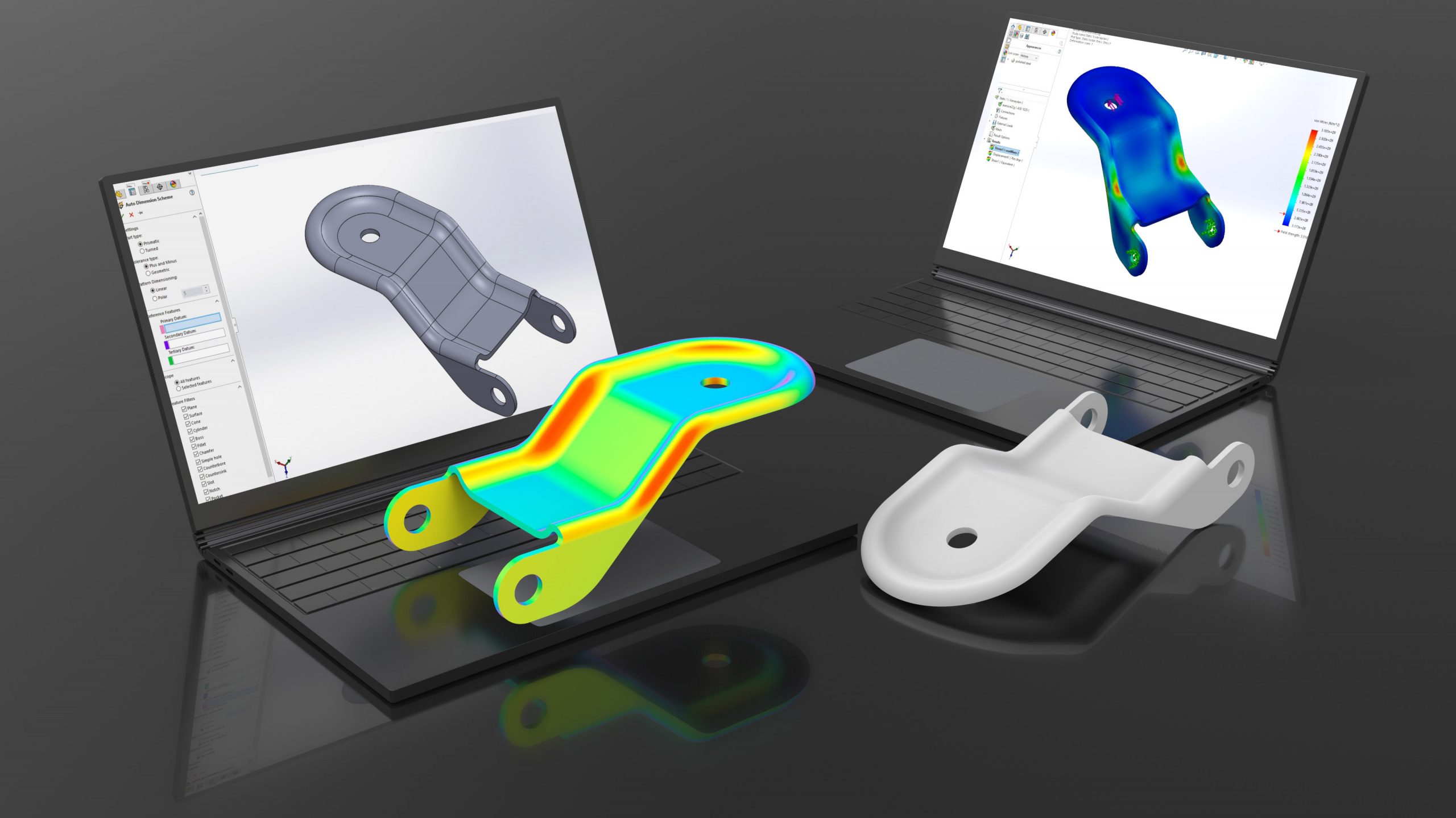

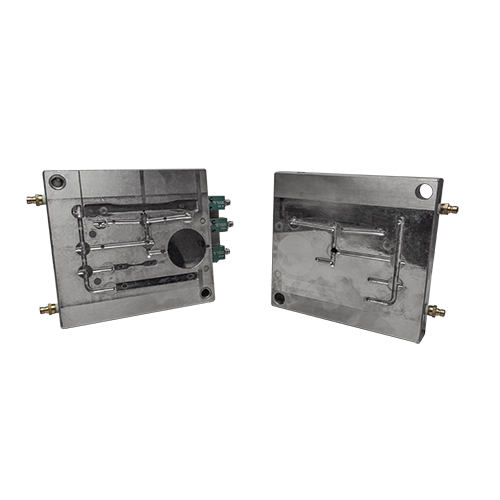

Mold Deflection Analysis

Mold Deflection Analysis helps to identify the area of the mold requiring the most support as well as the deflection magnitude of the parting surface. When mold deflection occurs, as do many undesired weight/dimensional variations or even costly mold damage. This analysis helps to determine the layout of robust support pillars or structures to optimize the design of ejector pins, cooling systems, and other mold components.

This proprietary approach was developed and validated using RJG’s mold deflection sensors in combination with FEA (finite element analysis) code.

Our Process

We start on the front-end of a product launch using engineering tools in order to make data-driven decisions to ensure that the end product meets your customer’s high quality standard.

Featured Deliverables

Moving boundary

Increase simulation accuracy to predict true injection pressure of the machine.

In Mold Rheology

Update material viscosity and thermal conductivity properties in the material database of simulation.

Core Deflection Analysis

Assure that the mold will have adequate support and prevent premature failure.

Full Project Report

Fully detailed recommendations for moving forward.