This tool lets the eDART® System become a valve gate sequence controller. It allows the balance of filling using opening by volume and sequencing of knit lines. The biggest benefit comes from using in-cavity pressure or temperature sensors read by the eDART system to control when the valves open or close. This can dramatically reduce the effects of material changes.

Available in a 60-day trial version.

About Valve Gate Sequencing:

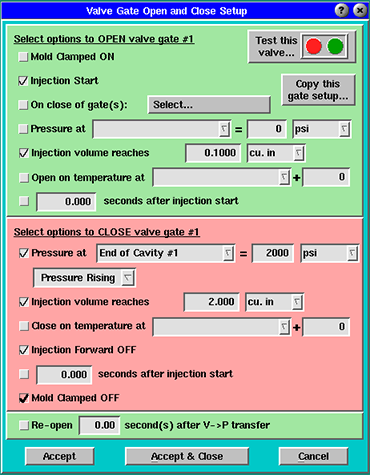

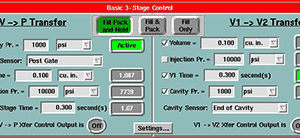

Valve Gate Sequencing is an optional software package for the eDART System™ that allows precise individual control of flow fronts and pressures in each cavity. An optimum process is achieved when it is coupled with cavity pressure control, which compensates for inherent material variation. Once installed, a process can be set up to open and close each gate independently using pressure, position, temperature, time, sequence inputs, or the operation of other valve gates. It is the key to setting up a robust process using valve gates and gives the operator the ability to manage pressures, flow lines, and knit lines while allowing for reduced clamp tonnage through alternate filling and packing. This precise control maximizes uptime, process capability, and performance.

There are three main types of valve gate applications: alternate, independent, and sequential. In an alternate application, one or more cavities start after one or more are finished, while an independent application starts all cavities simultaneously and closes each independently. With a sequential application, gates open as the flow front moves by, thus eliminating knit lines and “regional” multi-process disease. Another option is to attain a balance by using a late fill start for family molds—smaller parts start at a later volume so both parts fill at the same time.

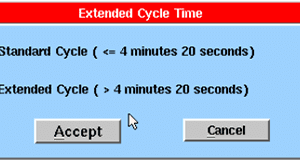

Valve gate sequencing is handled by the eDART™ while it’s performing other monitoring and control functions. The valve gate tool also transfers the machine from velocity to pressure (hold) once all of the valve gates have closed. This allows you to drop hold pressure and begin recovery (screw run) earlier, which may allow you to shorten cycle time. If hold pressure is needed to remove sinks, the valve gates may re-opened after transfer.

Features and Benefits:

- Allows precise, individual control of flow fronts in the cavity

- Maximizes uptime, process capability, and performance

- Independently controls gates using pressure, position, temperature, time, sequence inputs, or the operation of other valve gates

- Better part consistency over long periods of time in both family and multi-cavity molds

- Can enable molds to operate with reduced clamp tonnage

- Greater control over family tools with different processes in each cavity

- Increased control for removal or moving of knit lines