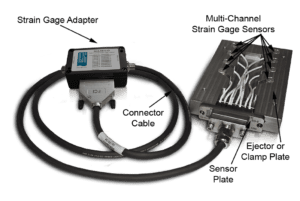

Multi-Channel Strain Gage System

Overview:

This low-profile, robust hardware system simplifies in-mold installations for molds with four or more sensors and saves real estate on the mold. This multi-channel cavity pressure solution, unique to RJG, allows injection molders to connect up to eight strain gage sensors to one connection point on the mold. Injection molders who want to reduce the footprint of hardware on their molds or save costs over other multi-cavity sensor solutions in the industry can now use RJG’s Multi-Channel Strain Gage solution.

System Components:

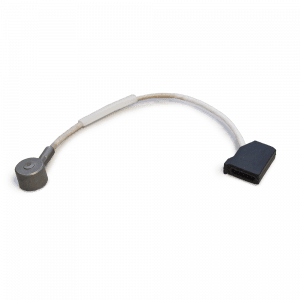

- Sensors: MCSG-B-127-XXXX

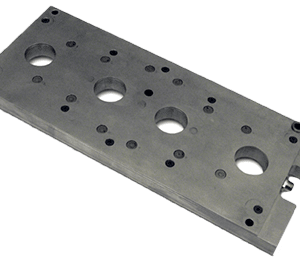

- Sensor plate mounted to the mold: SG-8

- Lynx™ Strain Gage Adapter: SG/LX8-S-ID

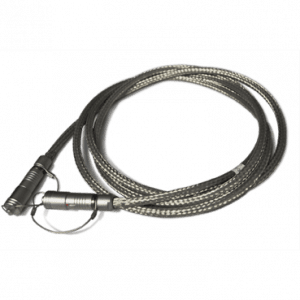

- Connecting Cable: C-SG/LX8-SXX

The adapter resides on the molding machine, allowing technicians to move molds easily by disconnecting and connecting the connector cable. A Lynx cable then connects the adapter to the eDART® System.

Features:

- Reduces the footprint of hardware on multi-cavity molds

- Saves costs over other multi-cavity sensor solutions in the industry

- Low profile and robust

- Simplifies in-mold installations

- Available in 50, 125, 250, 500, 2000, and 4000 pound force rating

- Ideal for 8, 16, and 32 cavity molds

Multi-Channel Piezo System

Overview:

This low-profile, robust hardware system simplifies in-mold installations and saves real estate on the mold. The multi-channel cavity pressure solution allows injection molders to connect up to eight piezoelectric sensors to one connection point in the mold. The interface with Mold-ID identifies the sensors and the mold to the eDART® System, so you can be sure you have the right mold running and the correct sensors selected.

System Components:

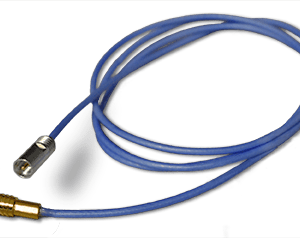

- Piezoelectric plate with Mold ID: PZ-4 or PZ-8

- Lynx™ piezoelectric adapter: PZ/LX4F-S-ID or PZ/LX8F-S-ID

- Connections cable: C-PZ/LX8-S-2M

Features:

- Reduces the footprint of hardware on multi-cavity molds

- Low profile and robust

- Simplifies in-mold installations

- Can be used with all piezoelectric sensors

- Adapter can be used with multiple molds—no need to repurchase with every mold

- Mold ID capability

- Signals from multiple sensors run through one connector

Lynx Embedded Sensors

Overview:

We put all the proven technology of Lynx™ digital sensors into the ejector backer plate with Lynx Embedded Sensors. The sensor electronics and head are entirely buried, eliminating outside cabling. Sensor locations and pin size files are pre-configured, making the setup that much easier. When the tool is hung in the press, all sensors are fully functional and properly named with a single cable connection from the mold to the eDART® System.

Features:

- Saves real estate on the mold

- Perfect for medium to high (4-32) cavity pressure sensor applications

- Instrument difficult molds without complex wiring and junction boxes

- Single Lynx connector for connecting the mold to the eDART

- Plate assembled and tested at RJG and guaranteed fully functional

- A rugged assembly that minimizes risk of sensor damage

- No removal or replacement of sensors or wires during maintenance—the whole plate can be set aside while working on ejector pins

- The sensor electronics are sealed in case water gets into the plate

- The time and cost of assembly and eDART System setup are reduced to a minimum

- The sensors work the first time, every time and continue working under the harsh conditions of the molding and tooling environments

US Patent # 8,425,217