Introduction: What Does Autonomy Have to Do with the Foundations of DIII?

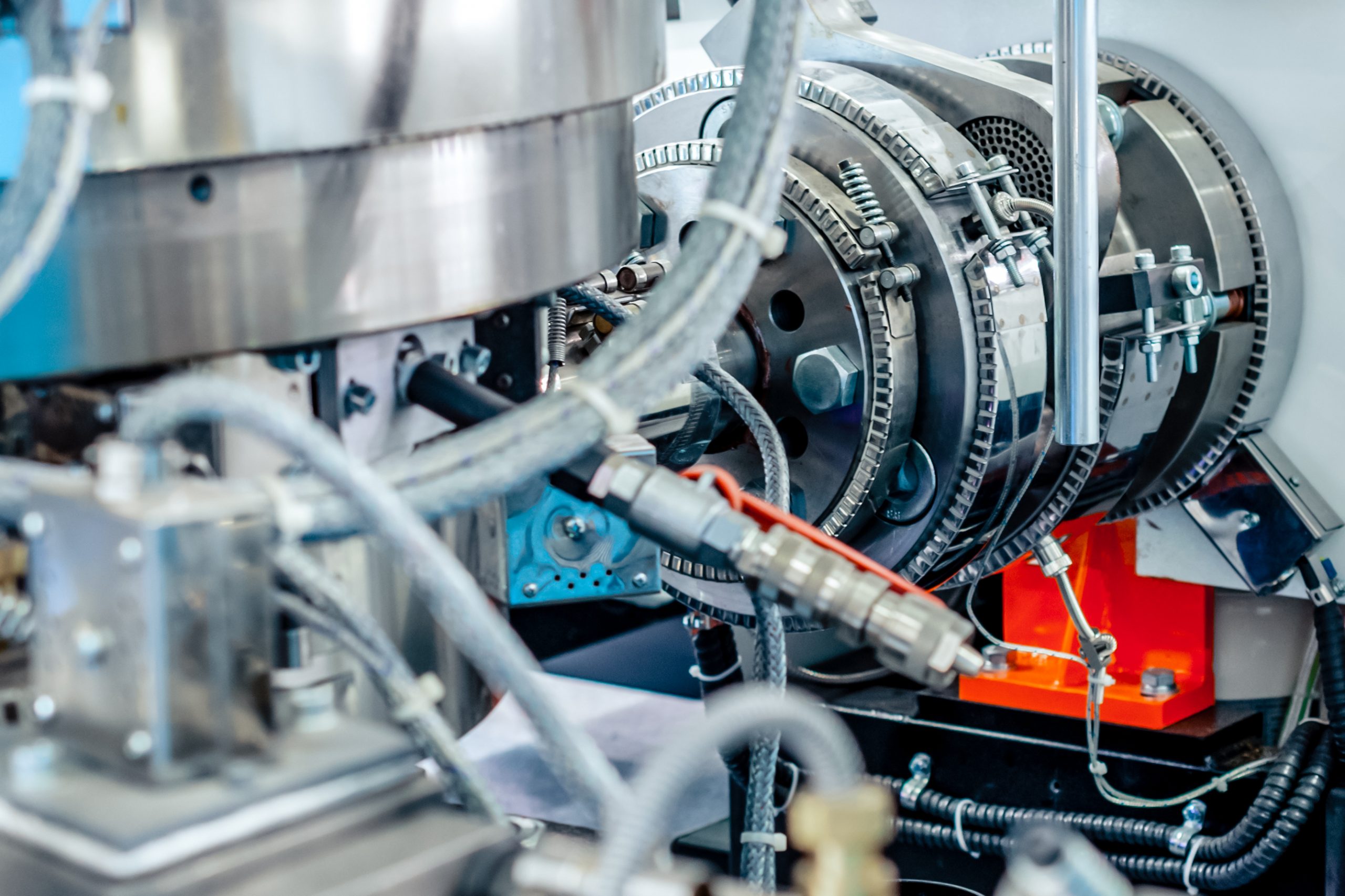

Automated injection molding has become a critical goal for manufacturers seeking higher consistency, reduced scrap, and greater production efficiency. As labor challenges grow and quality expectations rise, traditional operator-dependent molding processes struggle to keep up. Autonomous production concepts are no longer limited to robots or part handling; they now extend directly into process control itself.

One of the most effective ways automation is implemented at the process level is through RJG’s DECOUPLED MOLDING III, a scientific molding methodology that embeds automation into the molding cycle using sensors, data, and closed-loop control. Rather than relying on operator judgment or fixed time-based settings, this approach allows the molding process to self-regulate, adapting to real-time conditions inside the mold.

This article explains how DECOUPLED MOLDING III functions as a practical and proven form of automated injection molding, why it outperforms conventional methods, and how it supports repeatable, high-quality manufacturing in demanding environments

What Is Automated Injection Molding?

Automated injection molding refers to a manufacturing process where critical molding decisions are made automatically based on real-time data instead of manual intervention. While automation is often associated with robotics, true process autonomy focuses on controlling how plastic fills, packs, and solidifies inside the mold.

Key characteristics of automated injection molding include:

- Sensor-based process monitoring

- Data-driven stage transitions

- Reduced operator influence

- Adaptive compensation for material and environmental variation

The reality is, everyone wants to experience the benefits of automation; but nobody wants to trust the success of their business 100% to robots (and rightly so). The good news is, DECOUPLED MOLDING III meets all of these criteria today by using scientific principles and cavity-level feedback to control each phase of the molding cycle independently.

Overview of RJG’s DECOUPLED MOLDING III

RJG’s DIII represents the most advanced evolution of scientific molding available and is often referred to as the first real autonomous process control solution. It builds on earlier decoupled methods by introducing closed-loop cavity pressure control, which enables autonomous decision-making during the molding cycle.

Rather than treating injection molding as a single continuous event, Decoupled Molding III divides the process into three distinct, independently controlled stages. This separation is essential for achieving reliable automation and repeatability.

Process Decoupling: The Foundation of Autonomy

First Stage: Velocity-Controlled Fill

In the first stage, the mold cavity is filled to a predetermined volume at a constant injection velocity. This stage is decoupled from pressure, meaning the system focuses only on controlled flow, not force.

- Ensures uniform melt front advancement

- Reduces shear-related defects

- Establishes a consistent starting point for every cycle

Because the fill is controlled by position or volume rather than time, this stage already removes a major source of variability common in traditional molding.

Second Stage: Velocity-Controlled Pack

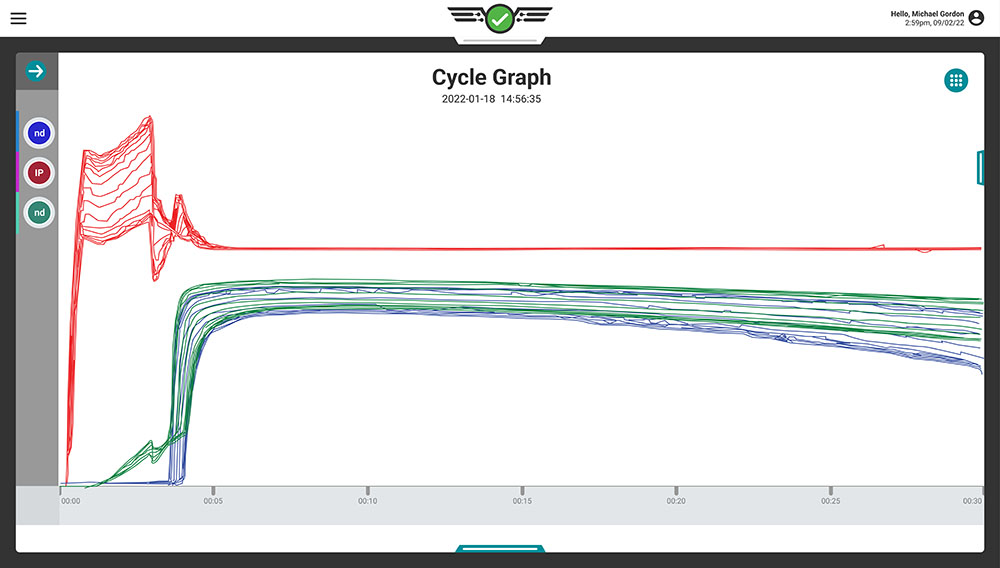

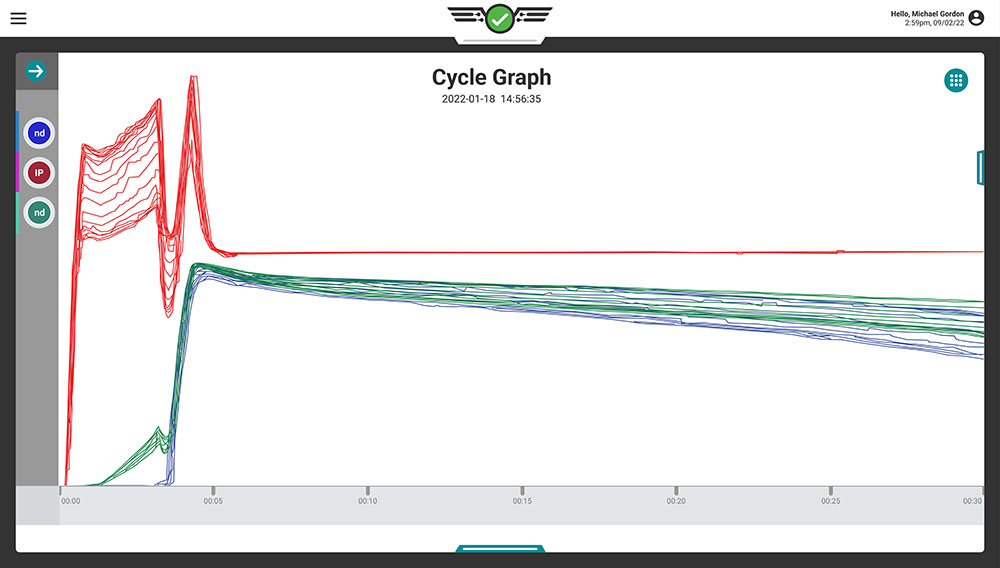

The second stage is where DECOUPLED MOLDING III most clearly distinguishes itself—and where automated injection molding truly comes to life.

Instead of switching directly to pressure, the system applies a constant packing velocity until a target cavity pressure set-point is reached. This velocity-controlled pack phase allows the process to compensate automatically for polymer shrinkage and material variation.

Once the desired cavity pressure is achieved, RJG’s CoPilot® System sends a signal to the machine to transition into hold. This decision is not based on time or operator judgment, but on real, measured conditions inside the mold.

Third Stage: Hold Pressure

The final stage applies a stabilizing hold pressure until gate freeze occurs. This ensures the part solidifies under controlled conditions, locking in dimensional stability and part consistency.

Because the earlier stages are already optimized and repeatable, the hold stage becomes a predictable and reliable final step rather than a corrective one.

How DECOUPLED MOLDING III Enables Automatonomous Injection Molding

In-Cavity Pressure Sensors

Cavity pressure sensors are the backbone of automation. They provide direct insight into what is happening inside the mold—something machine parameters alone cannot do.

These sensors:

- Detect exact melt behavior

- Trigger automatic stage transitions

- Provide real-time quality feedback

Scientific Switchover Logic

In DECOUPLED MOLDING III, switchover from fill to pack occurs based on position and cavity pressure, not elapsed time. This scientific switchover removes human guesswork and ensures consistency across shifts, operators, and facilities.

Adaptive Compensation

Automated injection molding must handle variation—and DECOUPLED MOLDING III excels here. The system automatically compensates for changes in:

- Resin viscosity

- Material lot variation

- Ambient or mold temperature

- Machine performance drift

This adaptive capability keeps parts within specification even when conditions change.

Advantages Over Traditional Injection Molding

Exceptional Repeatability

Each molding cycle mirrors the last because decisions are data-driven, not subjective. This level of repeatability is a defining feature of automated injection molding.

Reduced Process Variability

By eliminating manual adjustments and time-based settings, variability is dramatically reduced.

Faster Validation and Qualification

Scientific baselines minimize trial-and-error during setup, shortening validation timelines and accelerating time to production.

Improved Process Robustness

Automated switchover and closed-loop control allow the process to remain stable despite external disturbances.

Increased Uptime and OEE

By reducing quality-related downtime and scrap, manufacturers often see significant improvements in Overall Equipment Effectiveness (OEE).

Autonomous Injection Molding in Modern Manufacturing

As manufacturers move toward Industry 4.0, automated injection molding plays a vital role in:

- Lights-out manufacturing

- Medical and automotive compliance

- High-volume, high-precision production

DECOUPLED MOLDING III aligns naturally with digital manufacturing strategies by generating reliable data and predictable outcomes.

Frequently Asked Questions (FAQs)

1. Is automated injection molding the same as robotic automation?

No. Robotic automation handles parts, while autonomous injection molding controls the molding process itself using data and sensors.

2. Do I need special machines to use DECOUPLED MOLDING III?

No. Many standard injection molding machines can support it with proper sensors and control systems like RJG’s CoPilot.

3. How does cavity pressure improve automation?

Cavity pressure provides real-time feedback, allowing the process to make automatic, accurate decisions.

4. Is DECOUPLED MOLDING III suitable for all resins?

Yes. It is especially effective for materials sensitive to pressure, temperature, and shear variation.

5. Can this method reduce scrap rates?

Absolutely. Consistent filling and packing significantly reduce defects and scrap.

6. Where can I learn more about scientific molding principles?

RJG provides extensive resources and training on scientific molding methodologies. Ask for more details or request a consultation today.

Conclusion: The Future of Automated Injection Molding

RJG’s DECOUPLED MOLDING III is more than a process refinement—it is a practical, proven implementation of automated injection molding. By embedding sensor-based intelligence and scientific control directly into the molding cycle, it enables manufacturers to achieve higher quality, greater efficiency, and unmatched consistency.As the industry continues to move toward smarter, more autonomous manufacturing systems, DECOUPLED MOLDING III stands as a benchmark for how automation should be implemented—at the core of the process itself.