As industries seek to optimize processes and enhance product quality, AI emerges as a game-changer in the world of plastic injection molding. Here are 5 of the benefits that AI brings to this crucial manufacturing process.

1. Precision and Quality Enhancement

One of the primary advantages of incorporating AI in plastic injection molding lies in its ability to enhance precision and product quality. AI-driven systems, such as RJG’s MAX, can monitor and suggest parameter adjustments in real-time, ensuring consistent and high-quality output. This leads to a significant reduction in defects, minimizing the need for costly rework and improving overall production efficiency.

2. Predictive Maintenance for Increased Uptime

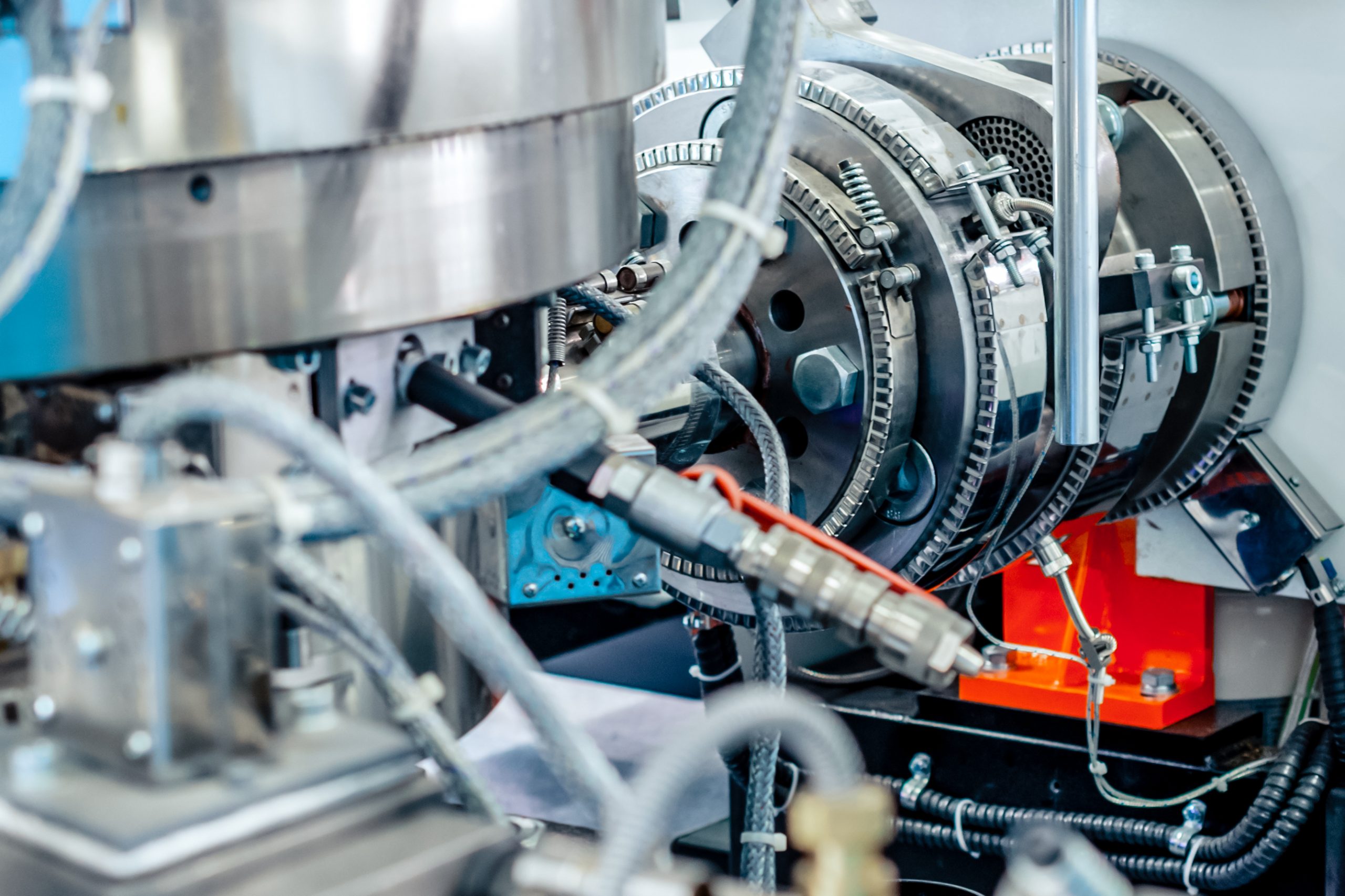

AI enables predictive maintenance by analyzing data from sensors embedded in machinery. By predicting potential equipment failures before they occur, manufacturers can schedule maintenance proactively, minimizing downtime and optimizing production schedules. This results in improved operational efficiency and cost savings.

3. Energy Efficiency and Cost Reduction

AI in plastic injection molding plays a pivotal role in optimizing energy usage. By empowering molders to maintain stable processes utilizing real-time data, AI helps reduce scrap, machine downtime, and unnecessary energy consumption. This not only contributes to sustainability goals but also results in substantial cost savings over the long term.

4. Advanced Process Monitoring

AI’s capability to process vast amounts of data in real-time facilitates advanced process monitoring. This includes monitoring the behavior of raw materials, detecting variations, and providing real-time assistance (MAX) to get a process back on track. As a result, manufacturers can maintain tight control over the entire production process, ensuring consistency and minimizing material wastage.

5. Shortened Time-to-Market

The agile and adaptive nature of AI expedites the product development cycle. By streamlining the injection molding process, AI contributes to shortened time-to-market for new products. This is particularly crucial in industries where rapid innovation and quick responses to market demands are paramount.

Conclusion

AI presents an unparalleled opportunity for enterprises to optimize operations, amplify productivity, and drive substantial returns on investment. AI’s versatility extends across diverse sectors, offering transformative solutions for challenges ranging from reducing scrap and machine downtime to empowering employees to refine processes and boosting production. However, it’s important to ensure you fully understand not just the benefits, but also the risks.

This blog post is an excerpt from our latest eBook, “A Comprehensive Guide to Artificial Intelligence in Injection Molding“.