Build consistent, validated processes for optimum output

An FDA compliant software application serving all injection molding industries

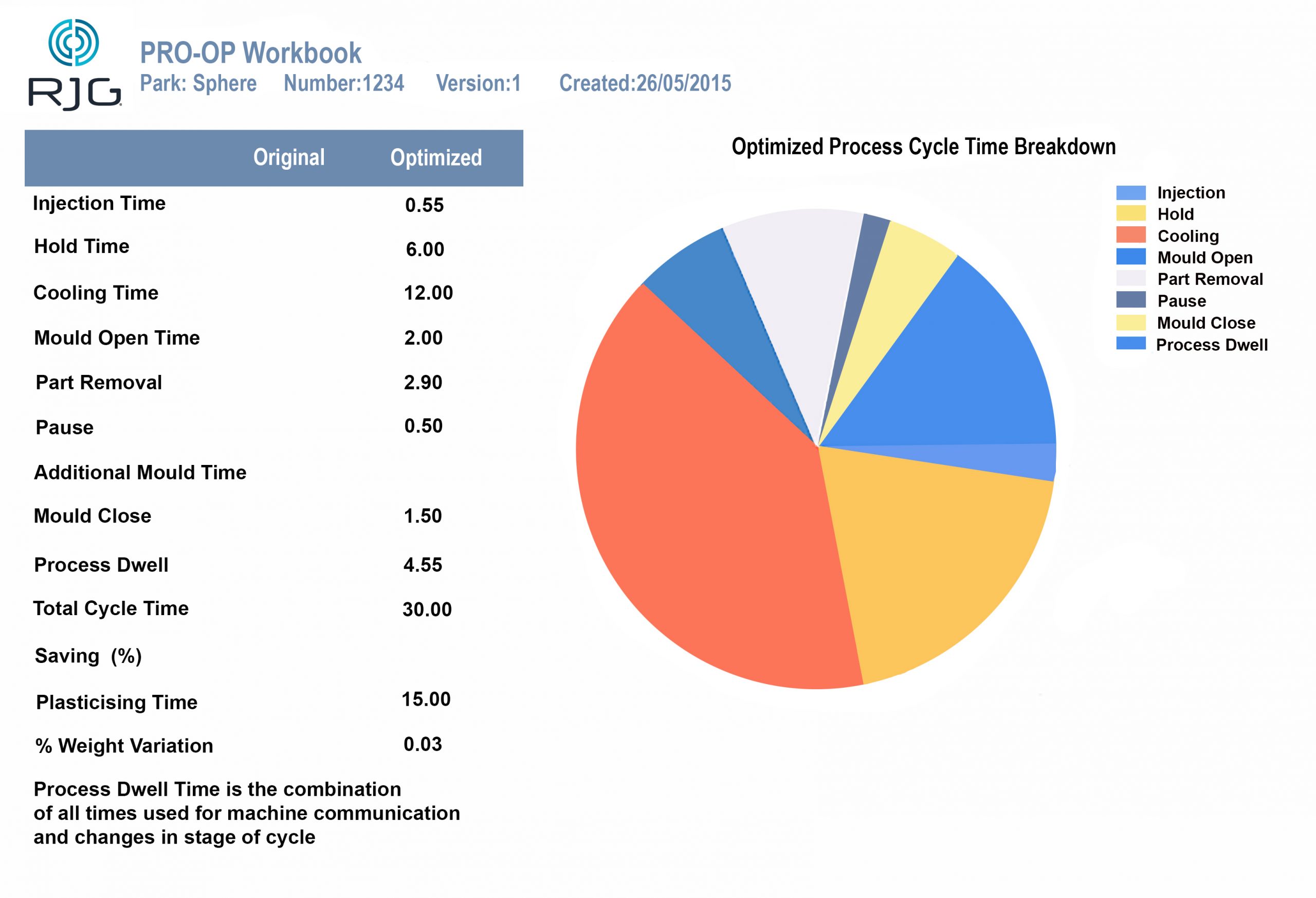

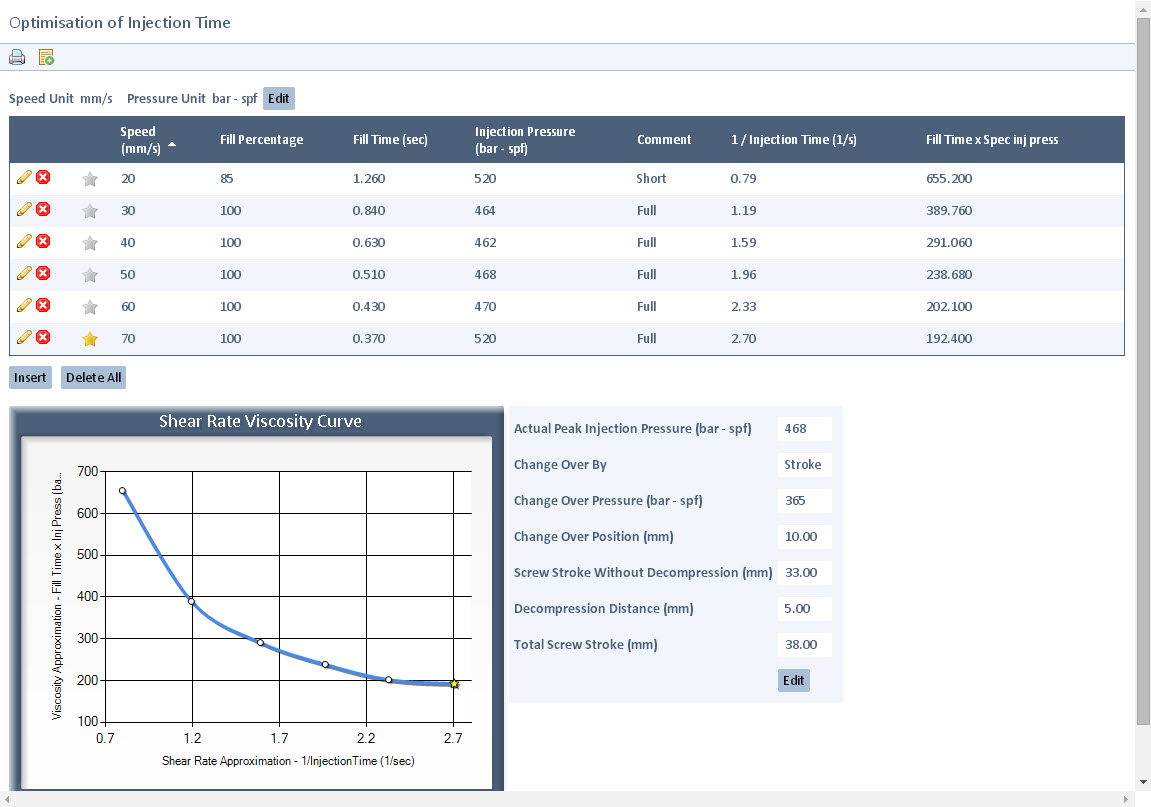

Maximize accuracy and output

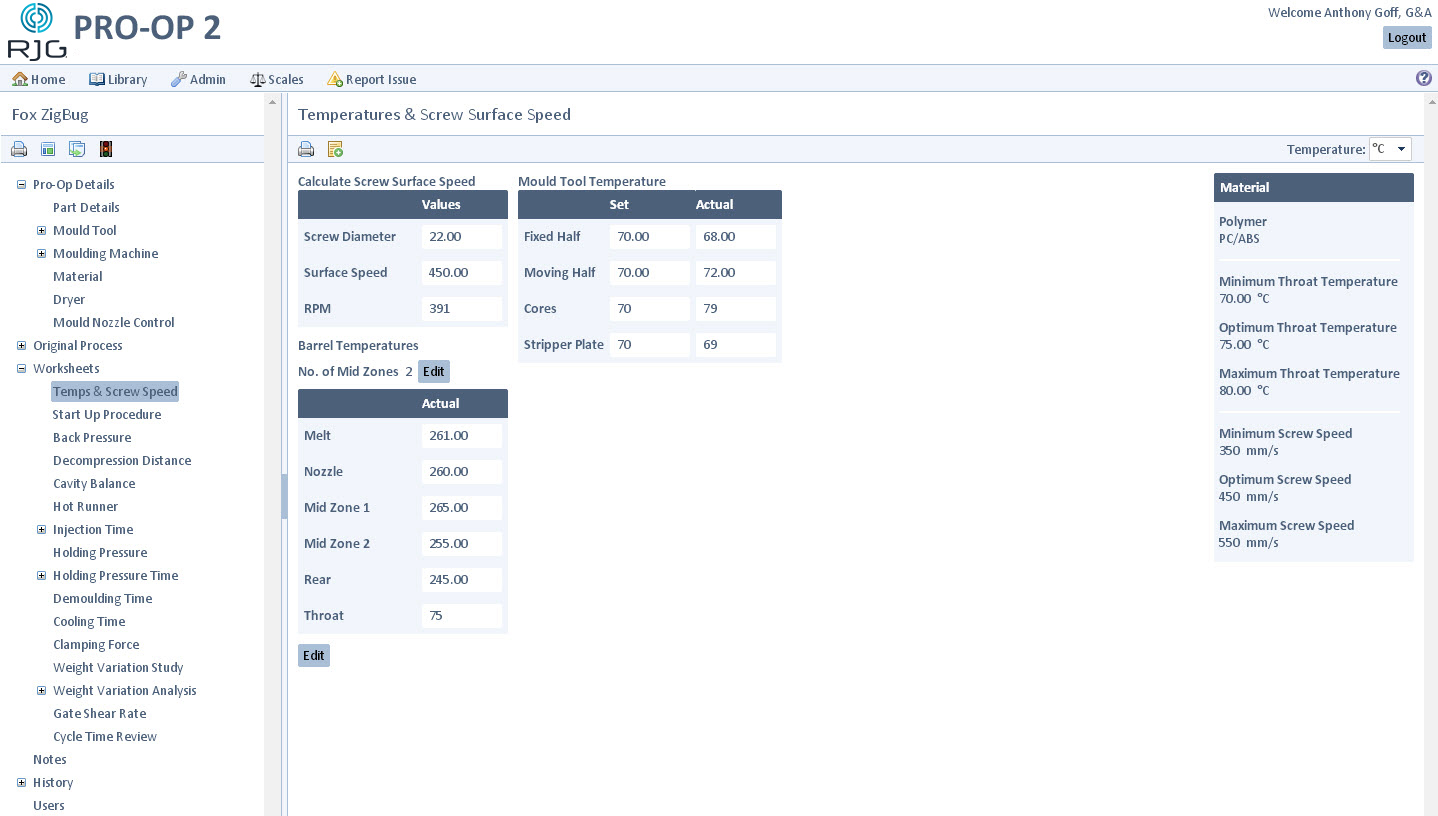

u003culu003eu003cliu003eStep-by-step walkthroughnu003c/liu003eu003cliu003eOnline instruction and supportu003c/liu003eu003cliu003ePart repeatabilitynu003c/liu003eu003c/ulu003eMold with confidence

u003culu003eu003cliu003eFDA compliant validation protocolnu003c/liu003eu003cliu003eComplete history tracking to reduce risknu003c/liu003eu003cliu003eDownloadable reportsnu003c/liu003eu003c/ulu003eMold with confidence

u003culu003eu003cliu003eSelf-validating system to prevent short-cuttingnu003c/liu003eu003cliu003eVersion controlnu003c/liu003eu003cliu003eInternal approval function with email trail and notificationnu003c/liu003eu003c/ulu003e

u003culu003eu003cliu003eInternal bug tracking and user feedback mechanismnu003c/liu003eu003cliu003eOngoing technical supportu003c/liu003eu003cliu003eAnnual functionality updates and options for bespoke customer functionalitynu003c/liu003eu003c/ulu003e