We have partnered up with HRSflow to provide an advanced process control solution, specifically for sequential valve gate control. We conducted a demonstration that included placing sensors in three different-sized cavities of a family mold. In addition, we strategically placed temperature sensors, which communicate with the advanced servo-driven valve gate FLEXflow hot runner system via the RJG eDART® system.

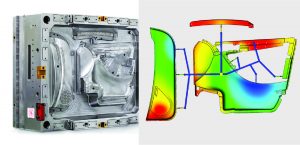

The mold, a demo family tool for automotive interior door panel parts, was designed in order to test the capability of the whole system to withstand difficult process conditions while still ensuring optimal part production. The system was first tested through advanced mold filling simulation to establish initial process parameters. A variety of cavity sensors were instrumented to monitor cavity pressure, mold temperature, and mold deflection and their response to the FLEXflow system controlling the process parameters of both the mold filling (speed and pressure control at each gate independently) and the valve gate sequencing.

“As a result of this collaboration, we are now sequencing the injection based on sensors in the mold,” stated Robert Harvey, North American Sales Director for HRSflow. “Sequencing based on mold-based events, rather than time or screw position, allows a process to be responsive to actual conditions in real time. HRSflow is very excited about this endeavor and what it can mean for the future of injection molding.”

Results showed that systematic engineering and simulation efforts, integrated intelligent molding systems and flexible servo-driven hot runner technology greatly minimized the risks associated with a new tool launch. In addition, it facilitated process development, assured consistent part quality in various molding conditions and allowed new design possibilities that would traditionally be excluded.

Using this newly designed valve gate control system opens up many opportunities for cost savings through larger process windows, increased quality, lowered scrap and increased yield. The near perfect repeatability of the servo valve gate systems ensures this benefit across all shifts and operator skill levels. Fallout due to quality of Class A surfaces can be minimized through greater control of flash, sinks, short shots, knit lines and warp. With greater control of flow regulation, clamp tonnage of the machine used for a given mold can generally be reduced, potentially allowing molds to run in smaller, faster, less costly machines. Independent control at each gate eliminates the processing compromise associated with family molds, allowing for the consolidation of components in molds to reduce the total project tooling costs.

“We are excited to work with HRSflow to enhance the process capability of the FLEXflow system by providing an additional level of control,” said Doug Espinoza, TZERO® Manager at RJG. “This collaboration makes what was once impossible possible—we can now provide a user-friendly customer experience while migrating even closer to industry 4.0 interfaces.”

About HRSflow:

HRSflow is a division of INglass S.p.A., headquartered in San Polo di Piave/Italy. It specializes in the development and production of advanced and innovative hot runner systems for the injection molding industry. The group of companies has more than 1,100 employees and is present on all the major global markets. HRSflow produces hot runner systems at its European headquarters in San Polo di Piave/Italy, in Asia at its plant in Hangzhou/China and at its facility in Byron Center near Grand Rapids, MI, USA.