Autonomy Meets Precision: The Impact of Cavity Pressure Sensors on Constant Pressure Molding

Abstract

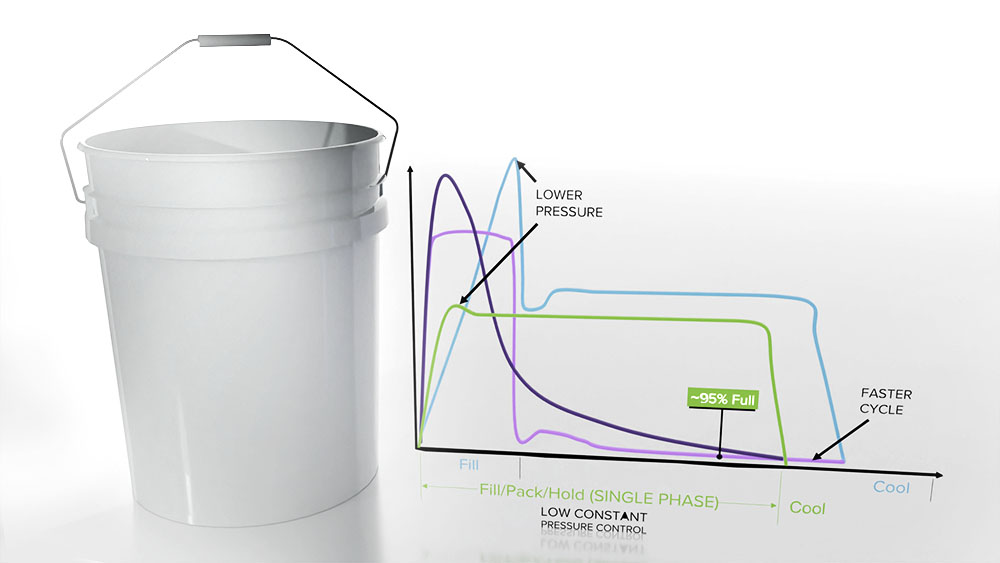

This white paper explores how combining RJG’s iMFLUX low-constant pressure molding with cavity pressure sensors enhances injection molding efficiency, quality, and adaptability. By validating the role of sensor inputs and adaptive algorithms such as Auto Viscosity Adjust (AVA) and Process Factor A (PFA), the study demonstrates how manufacturers can achieve tighter dimensional control, reduce energy use, and process recycled resins more reliably. Readers will learn how sensor placement, control strategies, and real-time feedback directly impact consistency, cycle times, and cost savings—providing a clear roadmap to smarter, more sustainable molding practices.