Mold Deflection Sensor

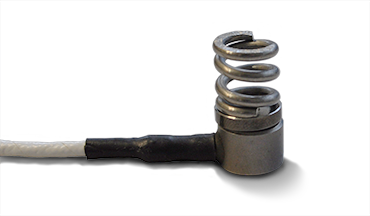

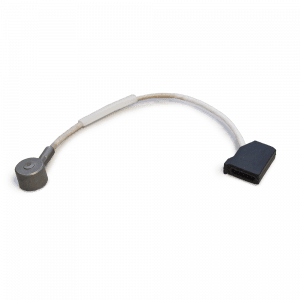

The Mold Deflection Sensor measures how much the mold parting line opens on each cycle. The indirect style sensor mounts in the clamp plate with a 5/16” ejector pin protruding .040” into the parting line area of the mold (not into the cavity). The pin transmits force through a spring to a Lynx™ force sensor that is calibrated to measure deflection.

When the mold clamps, the pin is pressed flush with the parting line, and the full force is applied to the sensor—this is recorded as “zero deflection”. As the mold “cracks”, the force decreases. For each incremental decrease in force, the sensor reports an increase in deflection. The sensors are calibrated to assume .040” (1.016 mm) maximum deflection.

Features and benefits:

- Auto calibration on each cycle with eDART® software

- Easy access to the assembly without disassembling the mold

- Minimize part dimensional changes from machine to machine

- Resolve mold deflection issues

- Resolve clamp force adequacy issues

- Resolve mold robustness issues