CoPilot Software Options

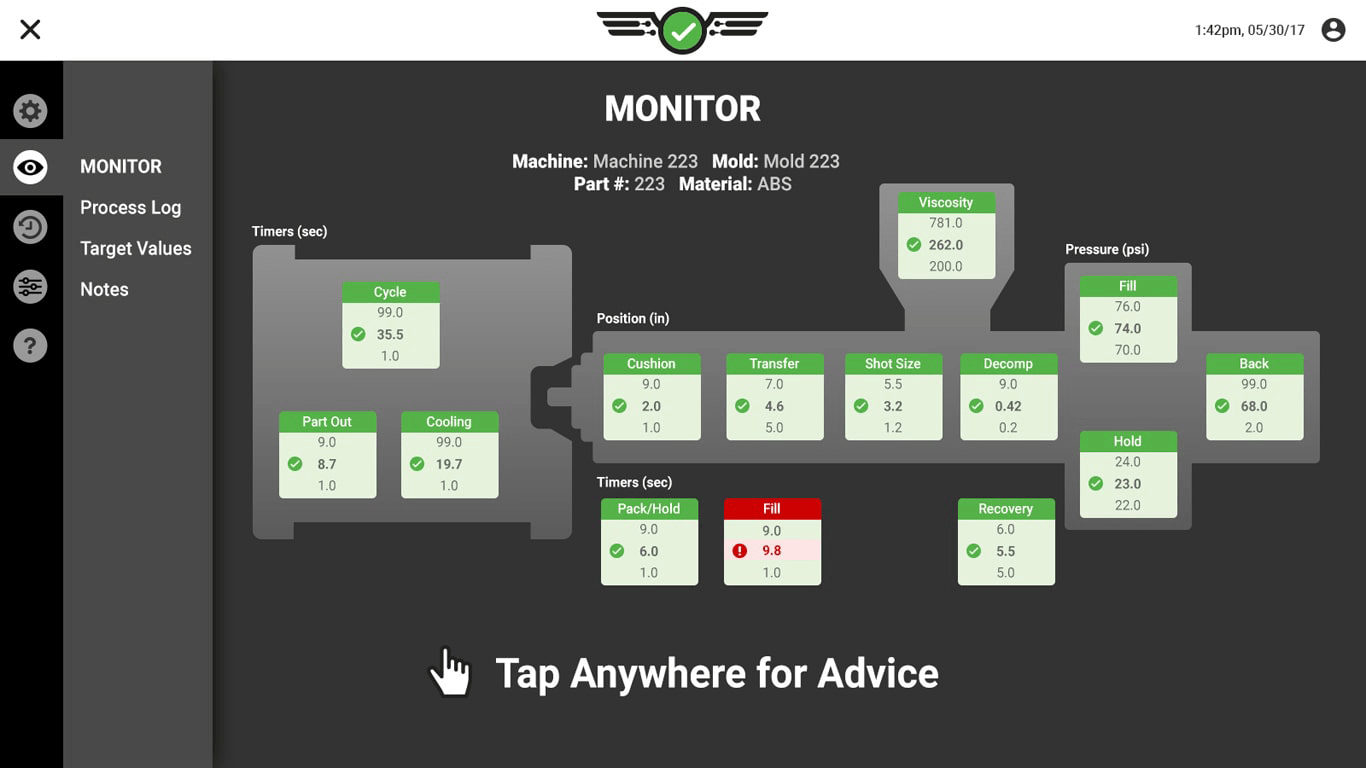

CoPilot®: The Original Solution for Injection Molding Excellence

The original CoPilot revolutionized injection molding with its focus on ease of use and quality assurance. Designed for molders of all skill levels, it provides: real-time process monitoring, defect prevention, and a user-friendly interface.

CoPilot® Go: Fast and Flexible Data Capture

CoPilot Go is designed for speed and efficiency, offering a portable solution that eliminates the need for complex machine control interfaces. Sort good and suspect parts with cavity pressure data, connect to any molding machine without requiring permanent hardware installations, and capture and transfer critical tool-tryout data effortlessly from setup to production.

CoPilot® Heat & Cool Control

Heat and Cool Control ensures your mold reaches the right temperature before injection begins, monitors cavity pressure to pack each part perfectly, and then automatically switches to the cooling phase at just the right moment.

Validated CoPilot® for Medical Molding

The CoPilot system is now validated for medical molding applications, offering the assurance you need for FDA-compliant processes. IQ/OQ/PQ tested the CoPilot has been verified to meet stringent FDA validation requirements and has been optimized for critical applications.