RJG Adds iMFLUX Technology to Injection Molding Solutions Portfolio

Traverse City, MI – May 1, 2025 – RJG, Inc., a global leader in injection molding training and technology, proudly announces they will be the point of purchase for pre-engineering, installation, and service for all hardware and software components of iMFLUX®. This strategic move further solidifies RJG’s commitment to delivering innovative, data-driven molding solutions while offering customers even more flexibility and control in today’s rapidly shifting manufacturing landscape. They will also serve as the hub for all services related to the iMFLUX technology, including Education, Process Engineering Support, Trial Services, and Parts. RJG will continue to support current iMFLUX users while welcoming future ones, backed by their top-notch support team and strong commitment to client care.

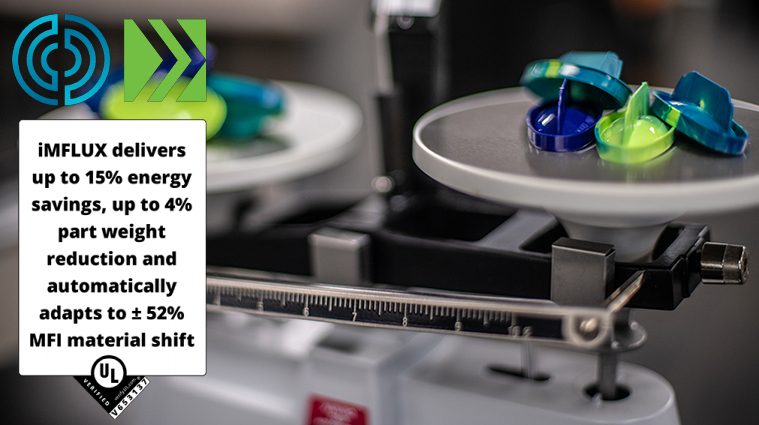

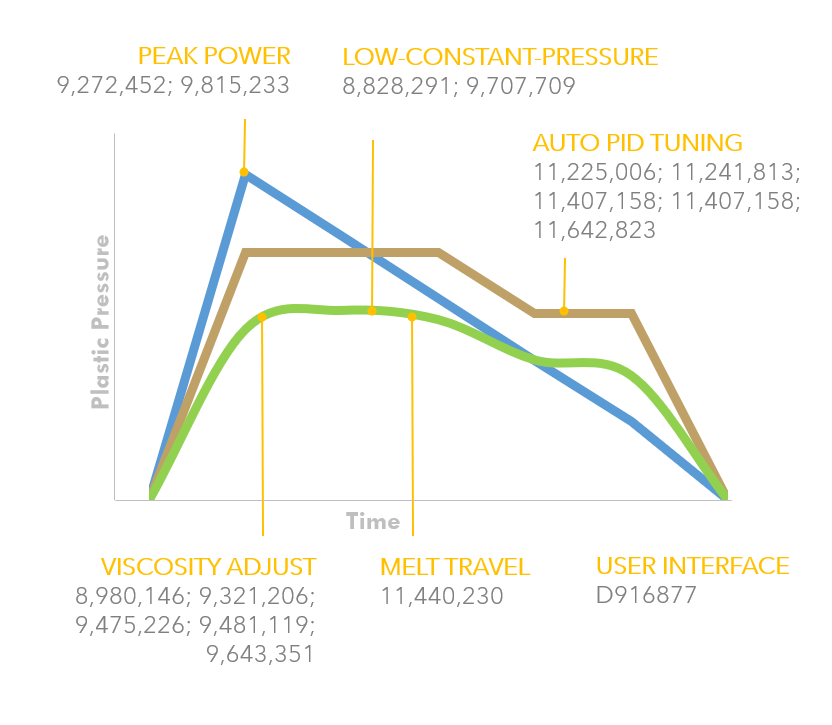

iMFLUX, previously operated as a subsidiary of Procter & Gamble, is known for its unique low constant pressure molding technology. With this addition, RJG customers now gain access to an additional option that supports machine downsizing, energy savings, and facility-to-facility mold transfer—critical advantages as manufacturers face high energy costs and reshoring efforts. As part of the agreement, Procter & Gamble is also transferring valuable intellectual property (IP) to RJG to support the continued advancement of molding technologies. This IP contribution will serve as a foundation for future innovations, enabling RJG to accelerate the development of cutting-edge solutions that further enhance quality, efficiency, and sustainability in the injection molding industry.

“We’re excited to bring iMFLUX technology under the RJG umbrella,” said Rob Nugent, CEO of RJG. “The combined strengths of RJG and iMFLUX give customers a powerful ability to produce quality parts with smaller machines, reduce material costs, and lower energy consumption—all while supporting cost-effective strategies. It’s about giving molders another option—another way to win in a highly competitive, cost-conscious market.”

By enabling molding at lower, more consistent pressures, iMFLUX allows manufacturers to run existing molds in smaller-tonnage machines, opening the door to significant energy savings and a more sustainable footprint. In addition, for companies reshoring tooling or shifting production between facilities, the technology reduces the need for identical presses, helping offset costly transfers.

iMFLUX complements RJG’s existing portfolio, including CoPilot®, The Hub®, and DECOUPLED MOLDING® Process training. This addition to their portfolio aligns with RJG’s long-standing mission to empower molders with the tools and knowledge needed to improve quality, reduce costs, and optimize processes.

For More Information: Please visit the RJG iMFLUX page.