Bridge the Skills Gap & Reduce Downtime with the Power of AI

This smart AI, powered by proven Master Molder techniques will give you an unparalleled level of control, efficiency, and quality never before possible.

ELIMINATE THE STRESS u0026amp;u003cbru003eFRUSTRATION OF DOWNTIME

Know the moment your process strays with real-time notifications.

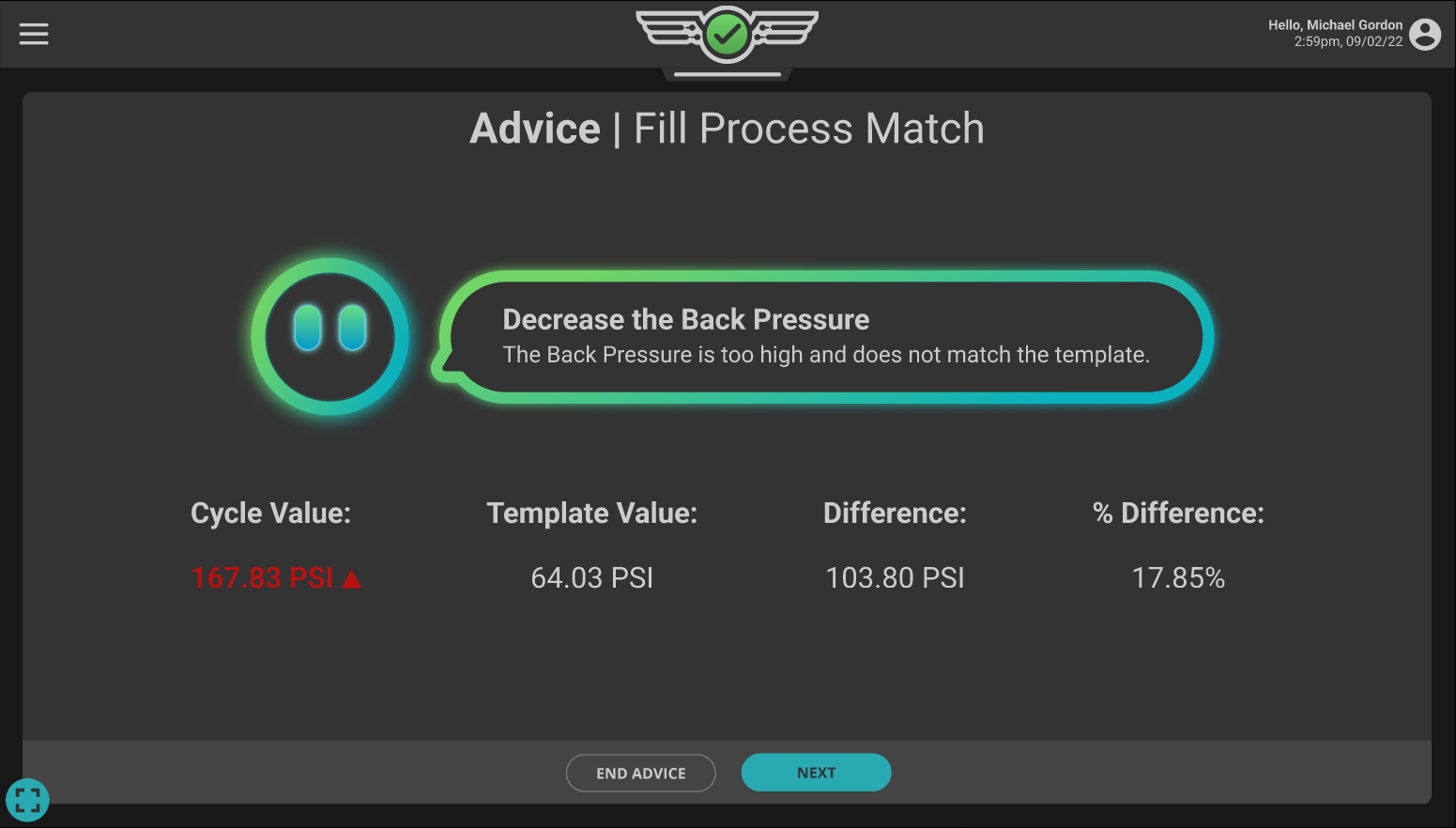

FIX PROCESSES WITHOUTu003cbru003eENGINEERING EXPERIENCE

Reduce wasted engineer time with simple step-by-step advise on how to fix a process.

LOWER PRODUCTION COSTS u0026amp; INCREASE EFFICIENCY

Improve cycle times, reduce waste, and more with complete process control and visibility.

AN EXPERT AT EVERY MACHINE

We understand the challenges and frustration that come with lacking

workforce knowledge, high production costs, and waste. That’s why we

created MAX, an Al powered advisor that works day and night to

ensure your processes are up and running how they should be.

And the best part, MAX is so easy to use that people with any

experience level can now fix a process!

“We are now able to make more than twice as many parts in the same amount of time–one process part output increased from 16,000 to 40,000 parts per day.”

-Christopher Weaver

Project Engineer, Flaxan LLC / Medron LLC

MAXIMUM EFFICIENCY

MAX works day and night to ensure your processes are up and

running how they should be. Run into a snag? MAX will be right by

your side to help make your process right again without the need to

track down the process engineer for every little fix.

No matter your skill level, MAX has your back!

- Reduce Waste

- Increase Part Quality

- Reduce Downtime

- Grow Profits

- Reduce Labor Cost

- Hit Deadlines

- Improve Output

- Lower Production Cost

Ready to get started?

Just three steps to peace-of-mind:

1. Complete the form below

2. One of our experts will reach out within a day

3. Start your journey to a more efficient, profitable production

EFFICIENCY & QUALITY NEVER BEFORE POSSIBLE.

Monitor and control injection molding processes to ensure high quality parts

Receive real-time, on-screen notifications when a machine is down or producing suspect parts

Get step-by-step advice for

fixing a process

Set alarm limits and

templates for process

matching

View data from each shot

Automatically retain suspect parts and understand what happened in the process

Access total part and process audit records

Build efficiency through process automation