Reducing troubleshooting time in the plastic injection molding process is crucial for minimizing downtime and maximizing productivity. Here are some strategies to help streamline the troubleshooting process:

1. Real-time Monitoring and Alerts:

Implement real-time monitoring systems, such as CoPilot, that are able to track critical process parameters, such as temperature, pressure, and cycle times. Real-time monitoring enables prompt identification of potential issues, reducing troubleshooting time by addressing problems early.

2. Documentation and Data Analysis:

Data! Data! Data! It may feel like a buzzword but, we promise, it’s a buzzword worthy of being talked about. Maintain detailed documentation of past troubleshooting experiences, including the identified problems, root causes, and solutions.This documentation serves as a valuable resource for future troubleshooting, allowing you to reference past solutions quickly and avoid reinventing the wheel.

3. Standardized Procedures:

Develop standardized troubleshooting procedures that outline step-by-step instructions for addressing common issues. These procedures should cover the identification of the problem, potential causes, and recommended corrective actions. Standardized procedures enable a systematic and consistent approach to troubleshooting, saving time and reducing errors.

4. Training and Skill Development:

Provide comprehensive training to your operators and technicians on troubleshooting techniques specific to the plastic injection molding process. Equip them with a solid understanding of the process, equipment, and common issues that may arise. Foster a culture of continuous learning and skill development to enhance their troubleshooting capabilities.

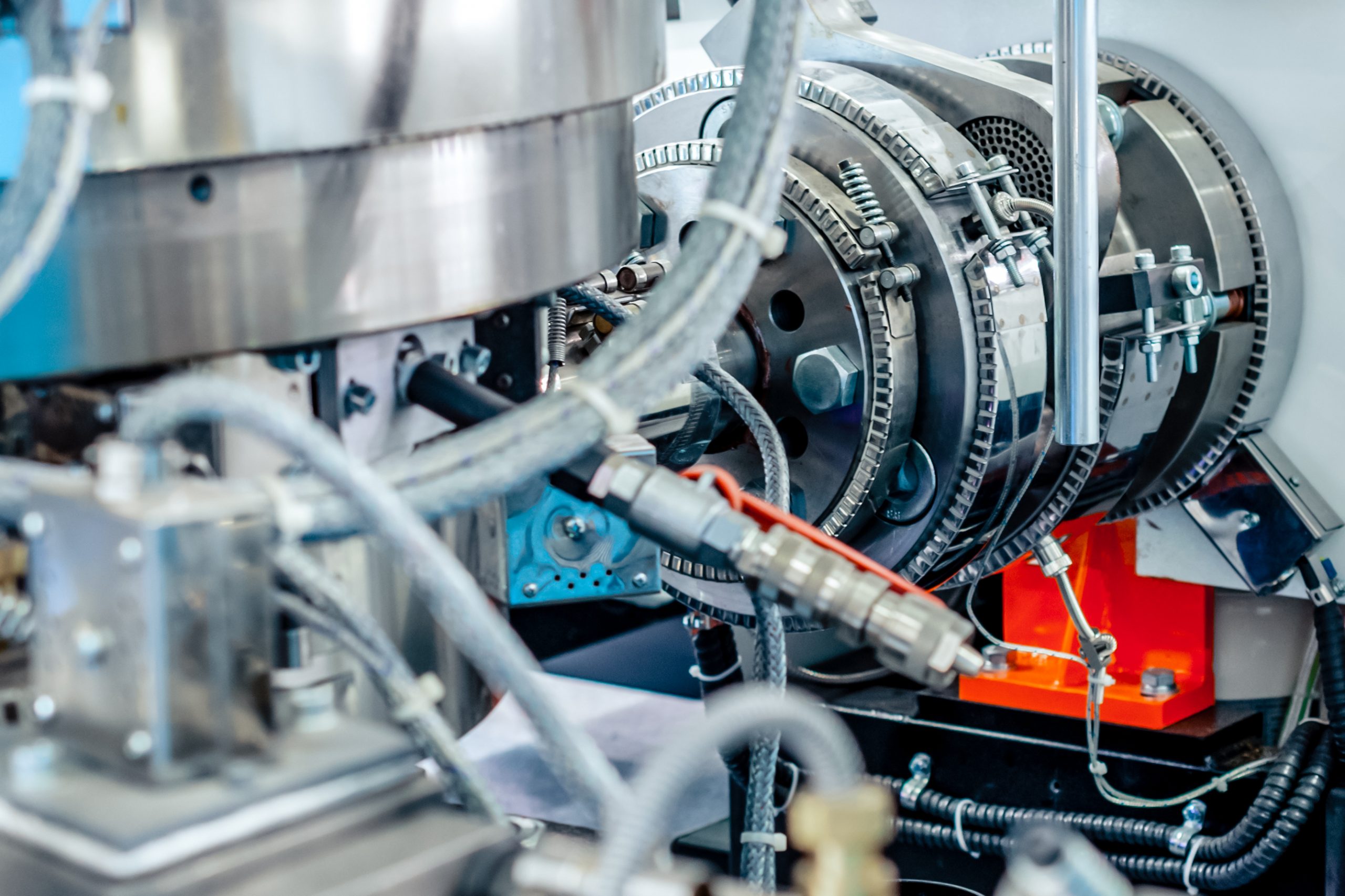

5. Equipment Maintenance and Calibration:

Regularly maintain and calibrate the injection molding equipment to ensure optimal performance. Preventive maintenance reduces the likelihood of unexpected breakdowns and issues. Establish a maintenance schedule and follow it diligently to keep the machinery in top condition.

By implementing these strategies, you can reduce troubleshooting time in the plastic injection molding process, minimize downtime, and improve overall productivity.