- WHY RJG?

- RJG SOLUTION SUITE

-

-

- OverviewDiscover our full end-to-end suite of injection molding solutions.

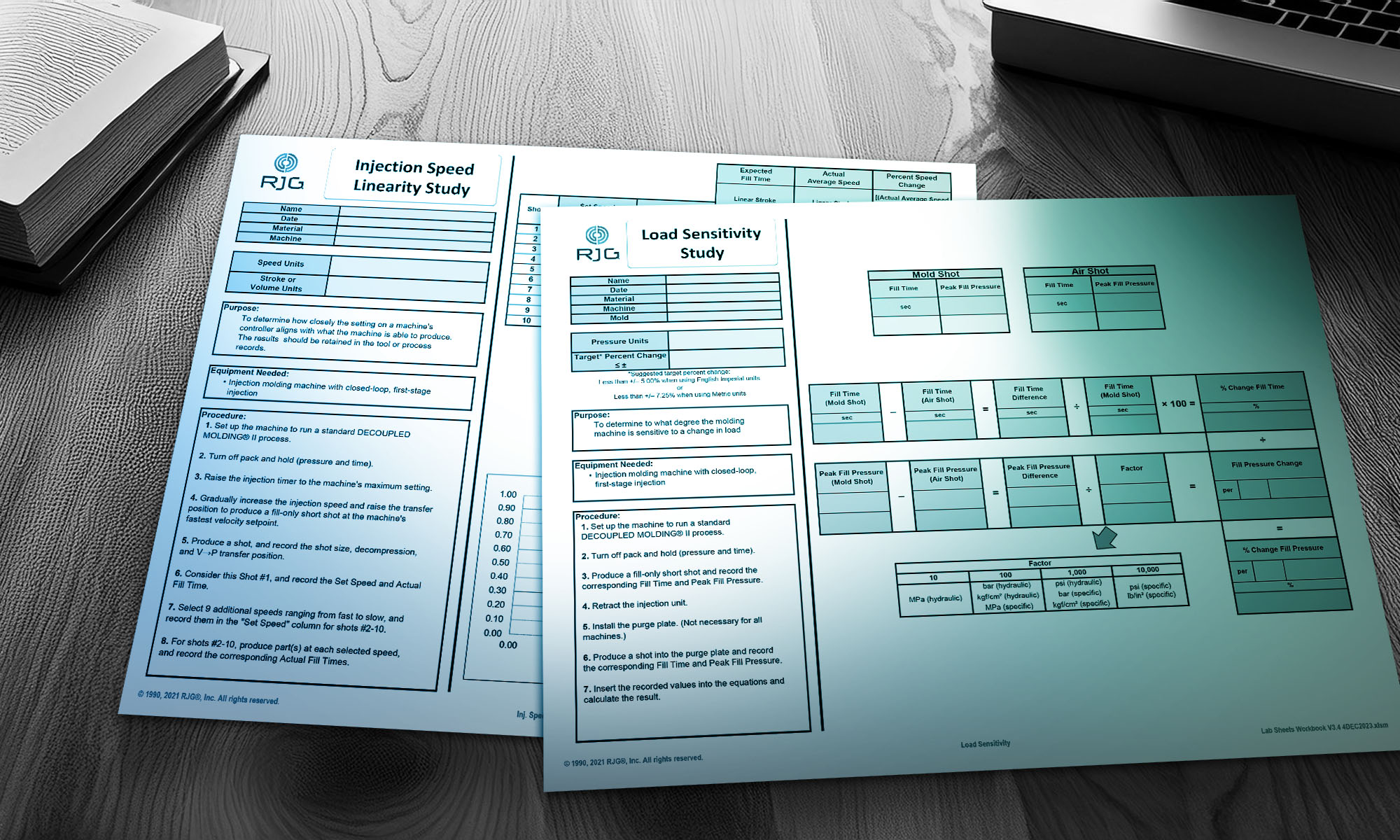

- TrainingInjection molding training improves quality, reduces cost, and raises morale.

- TechnologyGain a competitive advantage with the industry’s latest technology.

- ConsultingGet to market faster and resolve ongoing processing challenges.

-

-

- SUPPORT

- RJG TRAINING ACADEMY

-

-

- Why RJG Training?Discover the perfect course for you or take our training placement questionnaire.

- Public Course RegistrationRegister for in-person injection molding training at one of our global facilities.

- Online Injection Molding TrainingLearn at your own pace with online eLearning or with one of our expert trainers with virtual instructor led training.

- In-Plant CoursesHave several employees you’d like to train simultaneously? We’ll come to you!

-

-

- RESOURCE CENTER

- ABOUT RJG

-

-

- AboutLearn more about who we are, what we do, and why we do it.

- LeadershipMeet our fearless leaders.

- Consultant TrainersMeet our expert consultant trainers.

- TestimonialsHear what our clients have to say about working with us.

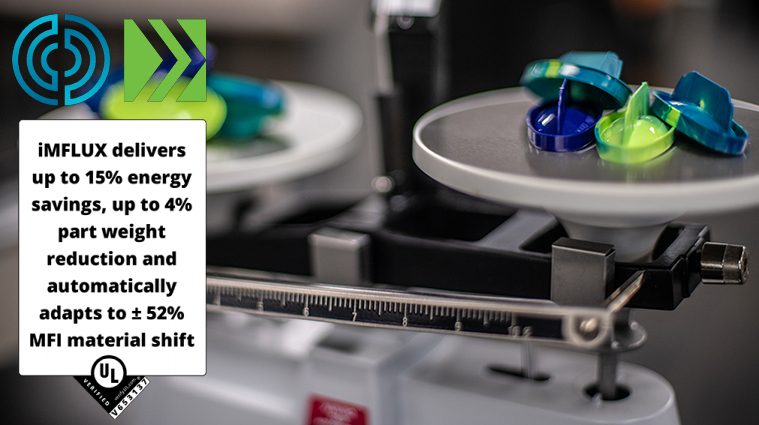

- PartnersMeet our awesome partners who allow us to do what we do.

- EventsSee our upcoming events.

- Mold Smart AwardApply for our annual RJG Mold Smart Award.

- CareersWe’re hiring! Check out our open positions.

-

-

- NEWSLETTER