In last months article “Ready-To-Go Molds with Cavity Pressure part 1”, we defined Ready-To-Go molds as a mold that can be put in the press and set up by the least qualified molding technician without breaking any rules. It can make parts predictably and quickly on cycle and allowed to run unattended without adjustment throughout the run.

Part 1 focused on fit and function. We discussed performing a pre-flight check on the mold to uncover any concerns before processing plastic. After pre-flight, a rigorous mold tryout is performed to wring out potential mold issues that may inhibit a robust production process. To properly perform the rigorous tryout, cavity pressure sensors are essential. The sensors give the tryout team real-time data allowing them to make accurate tooling adjustments. Information related to cavity-to-cavity balance, proper packing levels, cavity fill and pack times, and gate seal are just a few examples.

Part 2 – Process development and tool adjustment

Process development involves developing a robust process and then adjusting tooling to reach consistent part quality requirements. The process will be a DECOUPLED MOLDINGSM process, which allows for separation of the filling and packing phases of the process to gain better control. Filling will be done on the machine’s first stage, not pressure limited, and will be terminated on a stroke (screw) position with the cavities 95-99% full. Packing and holding will be accomplished utilizing the machine’s second stage pressure. Cavity pressure sensors will be used only to monitor the in-cavity conditions and repeatability of those conditions initially.

Filling the Mold

With the melt temperature within the material manufacturer’s recommended range, an in-mold rheology study will be performed. The rheology curve is used to guide in fill speed selection. Rheology data does not dictate fill speed; rather it provides information related to how different shear rates affect material viscosity and also the stability of the material viscosity at various fill rates/shear rates. Ultimately, the fastest injection speed that reliably produces quality parts will be selected. After setting the fill speed, the stroke distance is then adjusted to produce “fill only” short shots that are 95-99% full at the transfer position with no pack or hold.

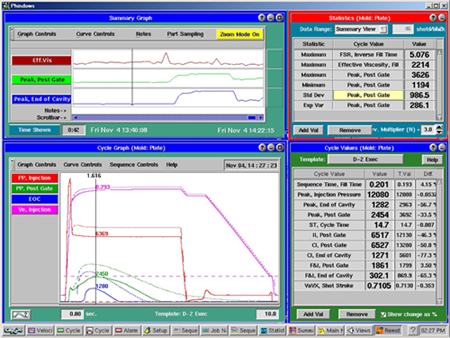

Process screen shot showing a template and a process change.

Packing the Mold

After filling, the cavities must be pressurized (packed) to minimize the effects of shrinkage during cooling. With a DECOUPLED #2 process, packing will be done using the machine’s second stage pressure. Monitoring cavity pressure, the machine’s packing pressure will be increased until a minimum pressure at the end of the cavity of 3,000psi or 200mpa is reached. Next, the machine’s hold timer is increased until the cavity pressure at the gate end of the part does not suddenly decay coincident with the end of holding time. This decay or “drop-off” in cavity pressure would indicate plastic discharging back through the gate.

Cooling

Having already checked the mold cooling system in the pre-flight stage, the cooling portion of the actual process must now be optimized. The part needs to maintain it’s desired shape and be able to withstand the forces of ejection prior to opening the mold. Achieving both of those goals within the desired cycle time can require a significant amount of experimentation, but the economic rewards are definitely worth it.

Capability Study

After development of the process, measuring true capability is the next step. The key here is to include normal variation in the study. This involves introducing a material viscosity change to the process and measuring the effect from inside the cavity. Because plastic viscosity cannot be held constant, ensuring real capability cannot be measured without accounting for normal variation. The cavity pressure sensors will illustrate actual in-cavity variations related to pressure gradient, changes in peak, time to peak, etc as viscosity variation occurs. This data is directly related to part quality characteristics such as flash, shorts, dimensional variation, strength, gloss, and part weight.

Tool Adjustments

The cavity pressure data and part quality inspection data from the capability study can now be used to make tooling adjustments. Because normal viscosity variation was introduced during the capability study, the steel can be modified based on the changes in part quality as a result of the viscosity variation. The goal is to make adjustments to the mold so that variations in viscosity during production will still render parts within specification callouts. It is one thing to produce a few acceptable parts in a controlled environment and send the mold to the production team. It is quite another to test true capability including normal process variation and then tune the mold steel so that all cavities run at the mean.

Any processor can make one good part with any mold. In order to stay competitive in today’s arena, however, molding companies need strategies to guarantee total quality from concept to production. Ready-to-go molds are an essential piece to the puzzle. Time wasted “tweaking” the process is expensive and has to be eliminated.

Process Template

Once the mold is Ready-To-Go and a robust process has been developed, the next step is to save an electronic fingerprint of the process by creating a template that includes all graphical and numerical data related to the target process. The tryout team can now send the Ready-to-go mold and the electronic template to the production facility. The production team now puts the mold in their machine and matches the cavity pressure template. This saves valuable time and paves the road to seamless production launches. The use of cavity pressure sensors allows everyone involved to make accurate decisions on what modifications need to performed, significantly reducing guess work.

If the final production process is not capable of producing quality parts long term, the next consideration would be to utilize the cavity pressure sensors for process control. In upcoming issues, we will discuss cavity pressure control and how the sensor can send signals to the molding machine based on cavity conditions to reach the highest level of process capability.

To some, having molds that are “Ready-To-Go” may seem like a concept that is unachievable. It is a methodology, however, that streamlines product launches and will ultimately decide the difference between surviving and thriving for molding companies in the future.