Tool launches are stressful. They’re time-consuming, labor-intensive, and extremely costly. Mix into it a global operation with multiple launches across multiple countries. Then throw in a dash of language barriers and a smidge of button pushing, and you have a recipe for disaster.

What if we told you there was a way to launch dozens of tools simultaneously around the world with no rework and good parts from the first shot? Then walk away from it all with fully standardized, highly efficient processes in place to ensure consistent quality across all of your machines.

Sound like a giant, scary undertaking? Don’t fret.

We recently released a whole new strategic offering that walks you through everything—from part design to the tool launch and into production. Below is an example of how we helped one company successfully launch over 30 tools around the world. Enjoy!

The Process

One of the biggest factors that lead to such a successful endeavor was our ability to leverage our global team to collaborate with each of their facilities around the world. We were all speaking the same language. Literally.

We started the project with simulation and design consultation to ensure that the part would meet expectations when it was actually molded. Design is a huge part of every tool launch, and missing the mark can lead to extremely costly rework and downtime in the future.

Our TZERO® team provided design, material, and process analysis for all 30+ molds. We also exported an eDART® template, a forecasted setup sheet, and an initial cavity pressure sensor analysis. The machine and mold would then be ready based on data-driven decision making the second the tool was installed.

Our customer support, TZERO, and sales teams worked together to determine eDART, CoPilot®, and sensor requirements and recommendations for each mold.

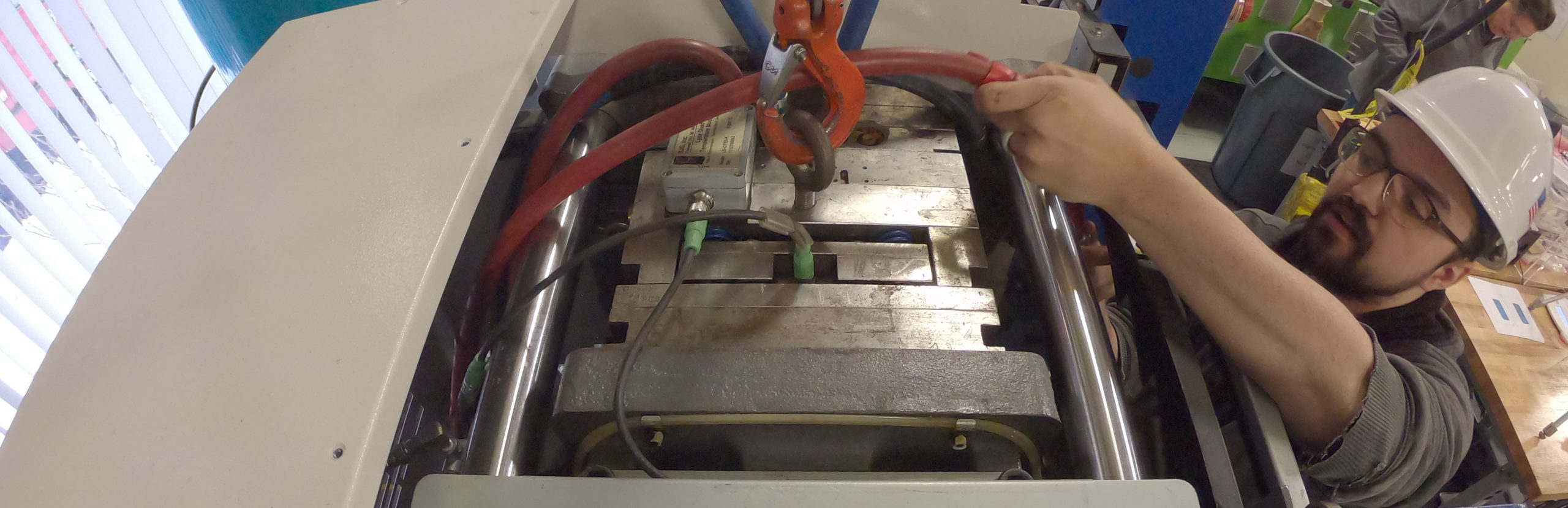

The tools were built and trialed in India using the eDART. The forecasted setup sheet was used as a starting point, then a DECOUPLED MOLDING® III process template was developed and optimized.

All of the critical dimensions were within specification with absolutely no rework.

We then converted the eDART templates to CoPilot templates, shipped molds to the US, and entered the setup sheet settings from the trial in India.

The template was matched from India, and all critical dimensions were again within specification.

To supplement the newly launched molds, we provided onsite training and workshops to ensure everyone was on the same page and producing the same part time and time again.

Insights

This project involved essentially all of our global products and services and focused on the entire end-to-end launch process. It ended with perfect parts from the first shot and complete global standardization.

That’s powerful stuff.

But we didn’t do it alone, and it didn’t happen overnight. Our customer was fully integrated into the process, and it couldn’t have been done without their complete buy-in, expertise, and contribution. This level of implementation requires a significant investment of both time and money.

So why bother?

Because it’s worth it. Simply not having mold rework could potentially cover the cost of implementation. Think about it: machine downtime, mold shipping costs, rework costs, salaries, loss of revenue… all of it adds up. The cost of rework could end up in the millions. Easy.

But that’s just the beginning. In production, the cost savings in scrap, inefficient processes, employee time, machine downtime, and shipping bad parts is enormous. Not to mention the potential loss of business and your reputation, which is invaluable. Plus add on top of it the frustration of constantly fighting fires and wondering what happened the night before. Imagine if that all just disappeared.

Seamless tool launches are here, and we are continually evolving our products and services to make the process even better—get ready!